The quest for cost-effective and efficient materials in cable selection is ongoing. Aluminum cables, characterized by their aluminum core conductor, emerge as a focal point in this pursuit. The discussion frequently oscillates between the traditional, robust copper cables and the lighter, more cost-efficient aluminum power cables. But what makes aluminium cables a powerful contender in this field?

With further reading of the following blog content, we will gain a more comprehensive understanding of aluminium wires from different perspectives as they are introduced and compared to copper cables.

What are types of aluminum cables?

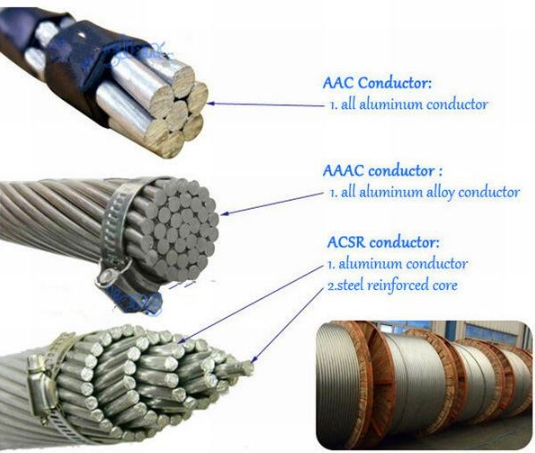

Aluminum cables are categorized into several types, each suited for specific applications. Notably, the All-Aluminum Conductor (AAC) is widely utilized for its excellent conductivity and lightweight properties. The All-Aluminum Alloy Conductor (AAAC) is distinguished by its enhanced strength and corrosion resistance. Meanwhile, the Aluminum Conductor Steel Reinforced (ACSR) offers a better solution for long-distance power transmission. Here are the details on construction and use:

All Aluminum Conductor (AAC):

- Construction: AAC cable is made of high-grade aluminum for excellent electrical conductivity.

- Use: AAC cables excel in urban environments where space is at a premium. It offers a reliable and economical solution for setups involving brief distances.

All Aluminum Alloy Conductor (AAAC):

- Construction: It utilizes a high-strength aluminum alloy for superior strength and corrosion.

- Use: AAAC cables emerge as the premier option for settings where durability is paramount, including coastal regions and industrial zones.

Aluminum Conductor Steel Reinforced (ACSR):

- Construction: ACSR cables feature an aluminum conductor with a steel wire armour ACSR cables offer an effective combination of strength and electrical conductivity.

- Use: Its structure excels in situations demanding long-distance, high-voltage performance.

Each type of aluminum electrical cable has its own strategic uses and advantages in the field of electrical engineering. We can also choose according to the specific requirements of the electrical infrastructure project at hand!

What is aluminium cable used for?

Aluminum cables are primarily used for long distance overhead transmission lines. Aluminum cables are lightweight and have high electrical conductivity. As a result, line losses are greatly reduced, which increases the efficiency of the transmission infrastructure. These characteristics are essential to provide for the transmission of power from the generating facility to the substation.

In demanding commercial and industrial environments, aluminum cables offer a reliable and cost-effective solution for managing large electrical loads. The ability of aluminum cables to face extreme temperatures continues to make them the preferred choice for powering machinery, equipment and facilities.

In aerospace and appliances, the outstanding properties of aluminum cables contribute to improved performance and energy efficiency. In aircraft, this means weight savings without compromising the integrity of the electrical system. While in electrical appliances, the conductivity of aluminum improves reliable power supply and operational efficiency.

What are the advantages and disadvantages of aluminum cable?

In light of the above, one might ponder the broader implications of using aluminum cables in complex electrical systems. How do these materials perform under the rigors of different conditions? Aluminum cable offers distinctive set of advantages and facing some challenges. Herein, we explore the pros and cons associated with aluminum cables to provide a reference perspective.

pros:

- Good electrical conductivity: Aluminum ranks just behind copper in terms of electrical conductivity.The feature guarantees efficient power transmission with frequent use in the distribution network.

- Light weight: Aluminum weighs only half as much as copper. Its lightweight characteristic highly beneficial for the installation of overhead cable power lines. This is because minimizing structural loads is of paramount importance in this application. This simplifies handling and installation while reducing labor.

- Economical: The aluminum cable price is relatively affordable. It results in cost savings in large-scale electrical installations.

- Ease of Installation: Owing to its lightweight nature and flexibility, aluminum cable can be deployed faster and more effectively compared to its heavier alternatives. This efficiency leads to reduced project durations and decreased installation expenses.

- Environmentally friendly: Aluminum is abundant and can be recycled. The use of aluminum cables minimizes the impact on the environment. The material can be reused without degrading its properties.

However, aluminum cables have some limitations in their use to a greater or lesser extent.

cons:

Oxidation: Aluminum cables tend to oxidize easily and we may notice oxidization in the long term, especially at the connections. Increased resistance affects efficiency. We need to use additional coatings to mitigate the effects.

Corrosion: The process that degrades materials happens when aluminium interacts with different metals in humid or salty conditions. Therefore, we need to carefully specify joints and fittings and select compatible materials to optimize service life.

Creep and swelling: Aluminum tends to creep under constant pressure and expands more than copper when heated. Therefore, specially designed connectors must be used. Connectors adapt to the properties of the material to provide a stable connection over time.

Copper Versus Aluminum Wire

Let’s say you’re embarking on a new construction project or renovating an old building. Choosing between copper and aluminum wire can greatly affect the upfront cost of a project, as well as its safety, efficiency and long-term maintenance needs. So the choice may seem complicated. Yet, by considering the following factors,we can further clarify the materials.

- Conductivity and efficiency

Copper wire has high electrical conductivity and low resistance. It is more efficient than aluminium, which means it requires less cross-sectional area to carry the same amount of current. Therefore, aluminium cable current carrying capacity is suited to applications where electrical losses and heat are minimised, especially in high efficiency equipment.

- Cost

Copper is more expensive. In this case, aluminium cable wire becomes a cost-effective alternative material. For projects that require a large number of wires and can accommodate higher resistances, aluminium’s lower cost provides an affordable solution without seriously compromising performance.

- Durability and Weight

Cu cables are heavy but long-lasting. Copper wires are less prone to abrasion having a long term stable performance. In contrast, aluminum is lighter in weight. It offers significant advantages in terms of ease of handling and installation in cases where a large amount of wiring is required. However, aluminum is less durable and has a higher expansion rate when exposed to heat. Therefore, when designing connectors we must carefully consider how to avoid loosening after prolonged use.

Aluminum cable conclusion

Essentially, aluminum cable has the utility of the wire solutions sector. Different Aluminum cable specification are used in wide range of applications in various fields and balanced advantages and disadvantages offer alternatives to traditional materials. However, whether you choose aluminum or copper cables ultimately depends on specific requirements and considerations. Alternatively, you can find out more about the products you need by email or on the ZW cable manufacturer website.

FAQs

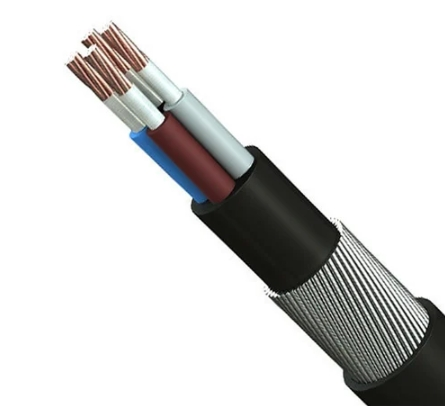

1. Can you use aluminium armoured cable?

Aluminum armored cables are indeed a viable option that is both economical and durable. Its sturdy construction secures protection from physical damage. Hence, it is suitable for use in various infrastructural and industrial environments.

2. How are Aluminium cable made?

First of all, we have to purchase high quality bauxite. This is the main ore from which aluminum cable is extracted. This initial stage lays the cornerstone for the quality of the aluminum cables produced.

Next, we extract aluminum from bauxite. This involves treating the bauxite with sodium hydroxide to form aluminum oxide. It prepares the alumina for the subsequent smelting process and guarantees that we extract the purest possible aluminum.

After extraction, the next step is to smelt the alumina to obtain the aluminum. We dissolve the alumina in molten cryolite. This method effectively separates pure aluminum from oxygen. The purity of the aluminum obtained is central to the production of high-quality cables.

We then move on to the wire drawing process, where the aluminum cable rods are drawn into fine wires. This step requires a certain degree of precision to achieve the required thickness and strength of the cable.

Finally, stranding and insulation marks the end of our cable production process. Here, we strand aluminum wires into cables and coat them with insulation. This protects the cable from the elements and also increases the safety of the application. Through this meticulous process, we produce aluminum cables that set the industry standard.