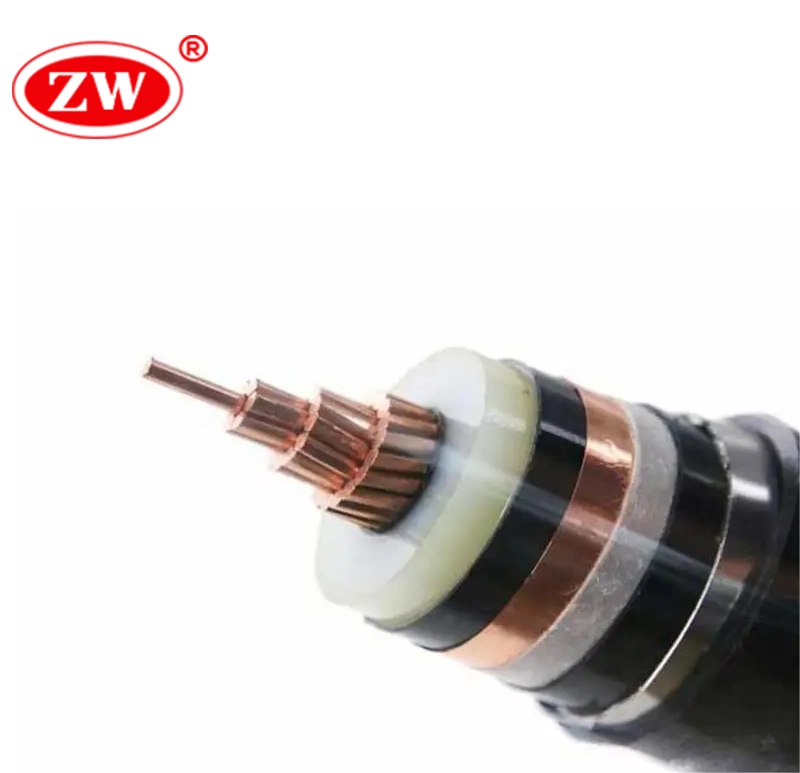

69 KV Cable Single-core Copper Conductor

- According to IEC and GB Standard

- Approved by ISO, CCC, CE

- Place of Origin: Henan, China

- Number of Cores: one

- HS Code: 8544492100

53 $ / Meter

5

69kv cable means a high voltage cable designed to carry electricity at 69,000 volts. Typically constructed of copper ,the 69 kV power cable is highly insulated with cross-linked polyethylene (XLPE) to prevent power leakage and ensure safe power transmission at high voltages. 69 kV transmission line plays an important role in transferring power from the generation source to substations in a variety of distribution systems, such as industrial facilities, commercial buildings, and utility networks, and it’s ideal for renewable energy projects.

69KV cable specification

- Conductor: Plain annealed copper Class 2

- Insulation: XLPE

- Shield Layer: Copper Tape

- Armored Layer: SWA or STA

- Related Voltage: 26/35KV

- Test Voltage: 220KV/5Min

- Temperature Range: Max 90°C, Min -20°C

Related Products

Get in touch with us today and see how we can help you reach your goals!