There are various cables available in the field of process automation for us to choose from. SY Cables, CY cables, and YY cables are often the preferred choice of reinforced cables within the same category. They are capable of withstanding the harsh conditions of heavy machinery and excel in transmitting signals and control between participating equipment. In this, we will delve into the details of SY armored cables as well as what differences exist between the different types. please check out our complete guide to learn more!

What is SY cable?

First, it’s important to understand the meaning of “SY” and what does SY stand for in cable? S denotes a steel wire braid; Y represents polymer PVC.

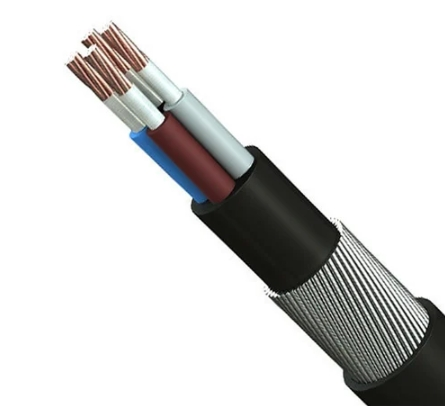

SY cable is a flexible armored cable braided with multi-core galvanized steel wire. Its construction entails a flexible copper conductor and PVC insulation enveloped within a transparent PVC jacket. The key layer of steel wire braid reinforcement provides excellent EMI protection and allows any internal corrosion or damage to be seen immediately through the transparent sheath.

Available in a diverse array of sy cable sizes and lengths, SY multi-core cables are designed to accommodate a wide range of flexible power needs, with common dimensions ranging from 1mm, 1.5mm, 2.5mm.

Difference between SY and CY cable

When selecting the appropriate type of cable for your needs, it’s common to encounter different options, such as SY and CY cables. So what are the subtle differences between the two types?

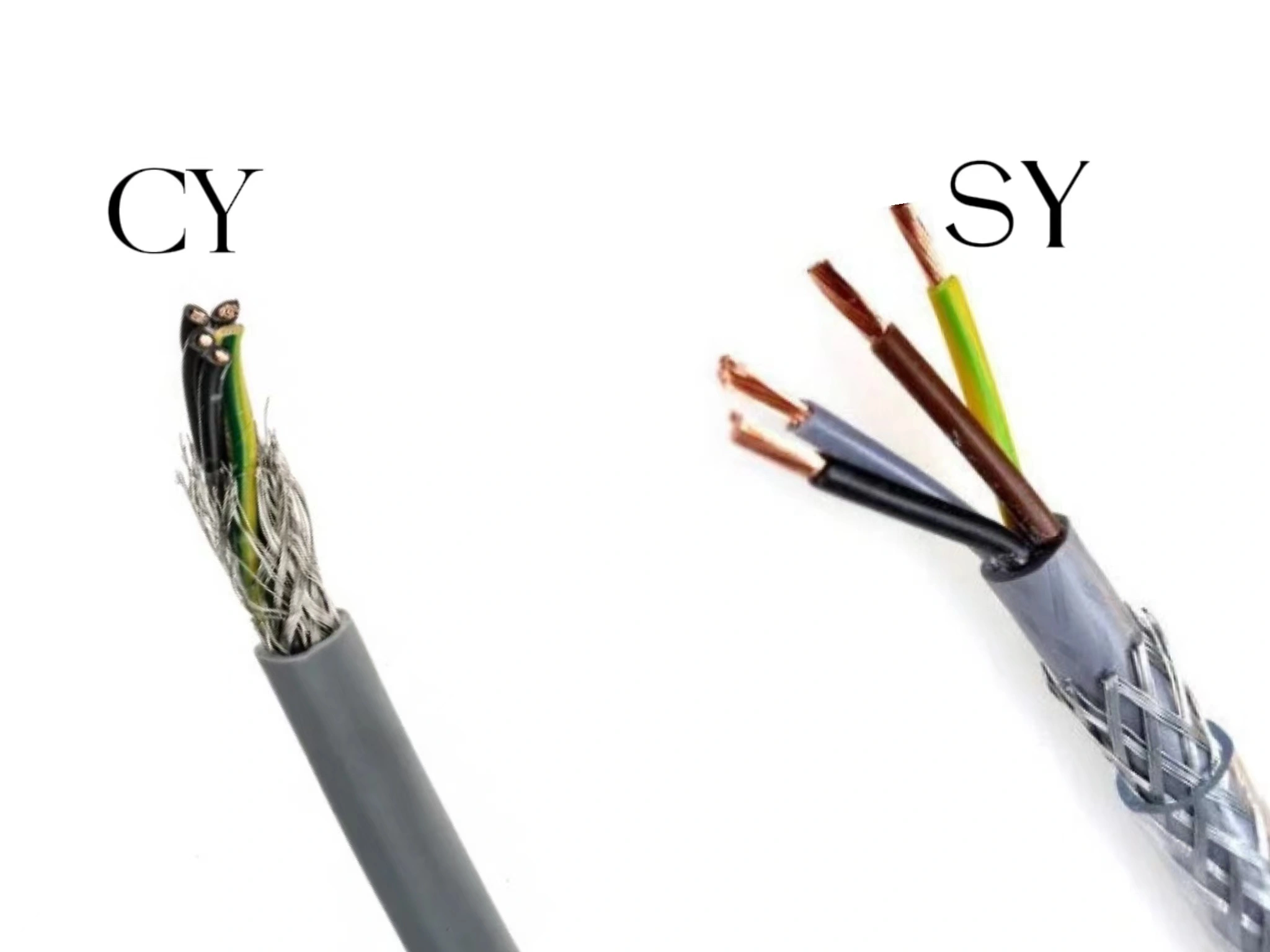

- SY flex cable is mainly used for mechanical protection and is made of braided galvanized steel wire. It is ideally suited to environments where physical stresses may affect the integrity of the cable. The transparent sheath design permits direct braid inspection, while color or number coding of the core streamlines cable management and maintenance efforts.

- CY cables are specifically crafted for environments where interference-free signal transmission is paramount. The design includes a tinned copper wire braid and an additional inner jacket. Together they make the cable immune to electromagnetic interference (EMI). It is especially beneficial if we are using it in environments where EMI can interfere with signal transmission and cause errors or malfunctions in sensitive equipment.

The distinction emphasizes the importance of choosing the right type of cable for the specific needs of an industrial setup:

while the mechanical ruggedness of SY cables provides physical protection, CY cables maintain signal integrity in environments sensitive to EMI. In addition, a similar NYY cable provides a durable solution for power and control in direct burial applications. Choosing the right cable secures optimal performance and reliability in industrial operations.

SY Cable Current Carrying Capacity

The current-carrying capacity of an SY cable refers to the maximum amount of electrical current that can safely flow through the cable without causing damage or overheating. Here, “current” refers to the speed at which charge is transmitted through a circuit. It is measured in amperes, often abbreviated as “amps.”

Below are some typical current ratings for SY cables:

- 6 amps

- 10 amps

- 12 amps

- 16 amps

- 18 amps

Selecting the correct current rating is essential for the safety and efficiency of electrical installations, preventing potential hazards related to overheating or cable failure.

What is SY Cable Used for?

SY cables are used in a wide range of important applications. Each application benefits from its unique properties to provide safe and efficient operation of vital equipment. Generally speaking, SY cables are predominantly utilized in automating industrial processes. For example:

Instrumentation

SY control cables are mainly used in automation equipment such as instruments and meters. It enables reliable transmission and protection of the signals necessary for measuring and controlling operational processes.

More detailed information about instrumentation Cable:Instrumentation Cable: What Are They and Differ Other cables

Control equipment

In control equipment, SY cables contribute to a safe and stable connection, which is essential for the efficient management and operation of machinery in various industrial environments.

Production lines

In production lines, the sturdy design of SY cables provides the necessary mechanical protection. It guarantees uninterrupted operation and prevents damage that may be caused by physical stresses.

Additionally, with their versatility and ability to withstand harsh environments, SY cables play a key role in maintaining operational integrity and safety in a wide range of construction, transportation and manufacturing applications.

Let’s move on to the necessary steps for stripping SY cables.

How to strip SY cable?

- Initially, we ascertain that the SY cable is fully disconnected from any power source, mitigating the risk of electric shock.

- Subsequently, we meticulously measure and delineate the precise segment of the cable designated for stripping.

- Utilizing a specialized cable stripping instrument, we execute a precise incision around the cable’s outer sheath, exercising utmost caution to preserve the integrity of the inner wires.

- Following this, we retract the outer sheath to unveil the inner cores, vigilantly inspecting for any inadvertent abrasions or incisions that might undermine the cable’s structural integrity.

- In instances where a braided shield is encountered, we carefully fold it back or trim it accordingly, adapting to the requirements of the specific task at hand.

- Concluding the process, we delicately remove the insulation from the individual cores, employing the stripping tool to achieve the requisite length, while keeping the conductor remains unscathed.

- The selection of our tools is dictated by the unique specifications of SY cable, guaranteeing a meticulous and professional preparation for either connection or termination.

SY Cable Conclusion

From the above reading on the characteristics of SY cables, we can conclude that SY cables are generally durable in construction and flexible in application. They have also become a key component in various industrial electrical cable.

If you are looking for this type of cable and a high-quality manufacturer, ZW Cable is an excellent choice. We offer a wide range of products that can be customized to suit your specific project requirements.

FAQs:

Can SY cable be used outside?

Although SY cables are very durable. However, it is important to note that most brands of SY cables are not designed for outdoor applications. Similarly, sy cable is not suitable for underground installation. The PVC jacket covering cables offers limited protection against UV rays, which can cause the cable to deteriorate over time. Exposure to UV rays weakens the cable, making it susceptible to damage and shortening its overall service life.

Therefore, if we must use SY cables outdoors, additional measures must be taken to protect them from direct sunlight. The use of protective coverings or installation of cables in areas where sunlight exposure is minimized will help to maintain the integrity of the cable and make certain its long-term functionality.

Additionally, if you need to install cables outdoors, it’s worthwhile to closely examine the various types of common outdoor cables available.

What is the difference between SY and YY cable?

YY cables are a type of flexible control cable that is unscreened and comes in a variety of core numbers and conductor sizes. They are particularly suited for use in environments where they are subjected to light mechanical stress.

SY cables feature a protective braid made from galvanized steel wire (GSWB), which significantly enhances their durability and resistance to mechanical stress. It attributes make SY control cables ideal for installations that are exposed to medium to high levels of mechanical stress.

Is SY cable fire rated?

SY control cables are designed for use as control cables in environments where a degree of mechanical protection is required. Particularly in environments where safety issues related to fire, smoke emissions and toxic fumes pose a threat to life. Its construction is designed to provide reliability and durability in environments where minor mechanical stresses are present.