Order Electrical Cable From ZW CABLE

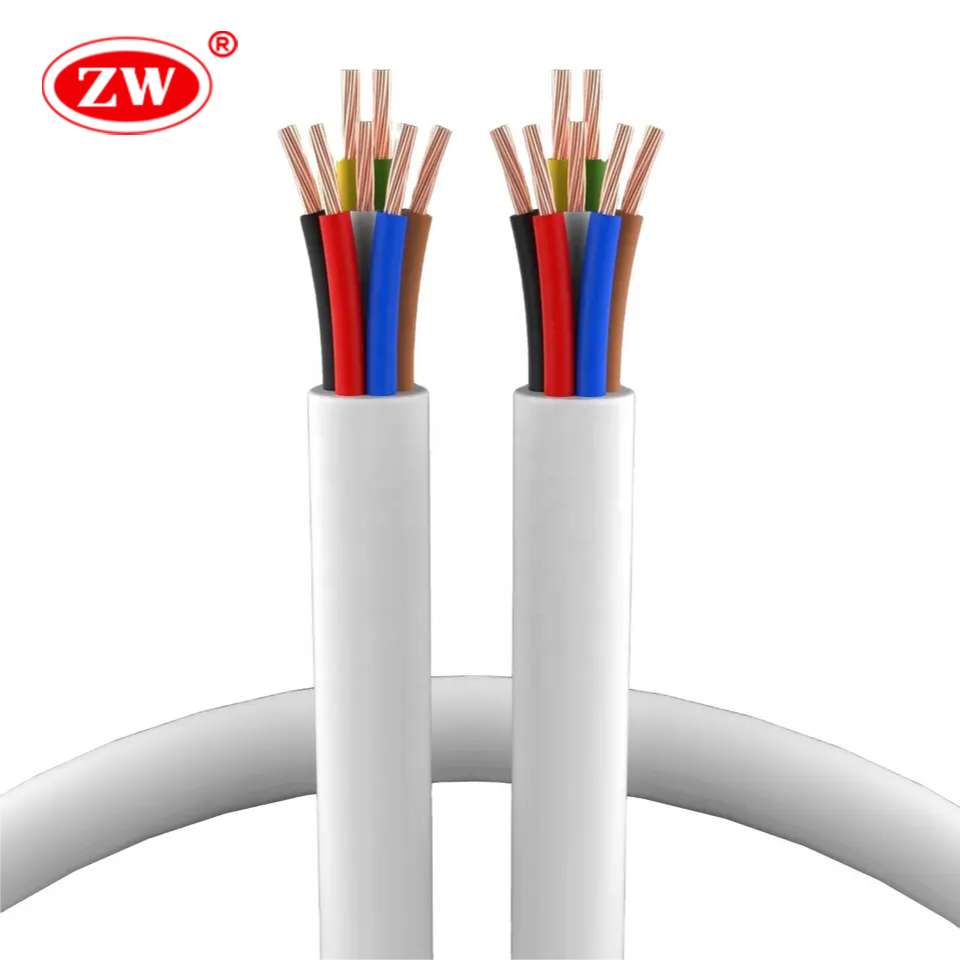

An electrical cable comprises one or more insulated conductors wrapped in polyvinyl chloride (PVC) sheath. The main purpose of electrical power cable is to transmit power. Electric cables utilize copper or aluminium as their conductor due to their excellent electrical conductivity and reliability. Electric cables are classified based on their voltage capacity, which is determined as low voltage, medium voltage, and high voltage. We manufacture power cable and have a large inventory of wires and cables under to 35 kV.You are welcome to place an order with ZW Cable. We offer factory prices for one meter cable.

Types of Electrical Cable

Armoured cable:

Apart from the conductor, insulation, and sheath, an electrical cable also includes an armour layer that protects against mechanical stress, moisture, and animal bites. The armoured layer enhances the durability and longevity of the cable.

Control cable:

For this type of electric cable is used to control electrical equipment to transmit signals, usually in industrial automation systems, etc.

High-voltage cable:

Designed for the efficient and secure transmission of high-voltage electricity over long distances. It is capable of operating effectively within the range of 35kv-110kv, making it suitable for use in substations and other related applications.

Medium Voltage Cable:

Medium voltage cables are available in the voltage range from 3.6 kV to 35 kV and can be used for medium distance power transmission cables.

Low Voltage Cable:

Lv cables are rated voltage of less than 1.0 kV, usually used in urban underground grids

Aluminium cable

Aluminum cables are frequently used for power transmission and wiring in “Commercial and industrial. Using aluminum instead of copper has several benefits, including lower costs and reduced weight, which can be especially helpful for transmitting power over long distances.