XLPE cable means cross-linked polyethylene, a type of cable xlpe insulation. It starts as regular polyethylene, then gets modified to crosslink the polymer structure. This process makes the material much tougher and longer-lasting. There are two main crosslinking methods: using chemicals or using higher-energy systems like microwaves.

Regular polyethylene has been used to insulate electric cables. But it has a flaw – it can’t take heat well. XLPE fixes that weakness. By transitioning polyethylene into XLPE, the cables can now work fine even when hot without harming their electrical performance. In this business, we’ll explore XLPE cables, from how they’re made to what they’re used for.

What is XLPE Cable?

XLPE cable means cross-linked polyethylene foam cable. It utilizes thermoset plastic as the base material.

In XLPE wires, polyethylene chains go through a chemical process called cross-linking during production. This cross-linking connects the polyethylene polymer chains together. As a result, the chemical and physical properties of the XLPE cable become much better. This enhanced insulation improves the desired attributes of the cable.

What Are The Benefits Of XLPE Cable?

The superiority of XLPE wire over PIL has been demonstrated by its dependability and safety, and both have numerous applications in factories. XLPE cables provide following advantages:

- XLPE provides safer and more accurate electrical insulation, improving power transfer efficiency. It reduces electrical faults leading to short circuits.

- XLPE cables are known for their high resistance to the harmful effects of temperature. They work well indoors or outdoors as they can operate at high temperatures.

- XLPE possesses high mechanical strength for use in different environments.

- XLPE cables have excellent chemical resistance to substances like oil, solvents, acids and alkalis. This extends their lifespan, especially in industries with frequent exposure to corroding chemicals.

When Should XLPE Cable Be Used?

XLPE cable should get utilized when reliable power transmission is required.

Here are some specific situations where it works well:

- Power Lines:XLPE copper cables adequately and securely transmit high-voltage electricity over long distances without losing power.

- Distribution Grids:These cables primarily get used within the distribution network. They connect substations to houses, businesses and industrial facilities.

- Industrial Uses:The XLPE insulated cables suit industrial applications nicely thanks to their chemical and mechanical strength. So they power machines and equipment excellently.

- Underground Installations:Their great resilience against water and chemical corrosion makes them the best choice for all underground laying projects in cities, roads and similar spots.

- Underwater Setups:XLPE cables also work for submarine power cables since they can withstand water pressure and environmental conditions.

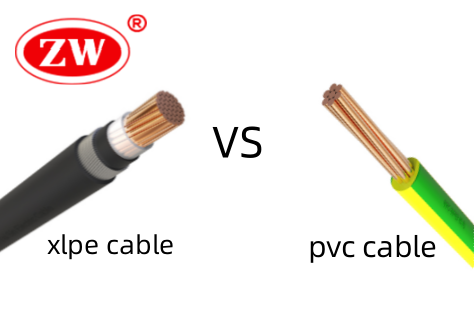

XLPE Cable VS. PVC Cable: What Is The Difference

When selecting a high rating electrical cable, XLPE and PVC are common options. Though both serve the same core functions, their performance varies across situations needing different device attributes.

| Attribute | xlpe insulated power cable | PVC Cable |

| Insulation Material | Better insulation properties with strong electric strength | Good insulation properties, but lower compared to XLPE |

| Temperature Rating | Resistant to higher temperatures without degradation | May encounter insulation degradation at higher temperatures |

| Mechanical Strength | High tensile strength, resistant to deformation and damage | More prone to sagging and potential damage |

| Chemical Resistance | Highly resistant to chemicals, suitable for corrosive environments | May degrade over time when exposed to certain chemicals |

| Environmental Impact | Better environmental performance in production and disposal | May release harmful substances when burned |

The optimal choice between XLPE and PVC cables depends on the specific application requirements and environmental factors to consider.

What Are The Different Types Of XLPE Cable?

XLPE cables come in the following different types.

- XLPE Insulated Power Cable:XLPE insulated power cables are engineered to transmit electrical power of various voltage classes.

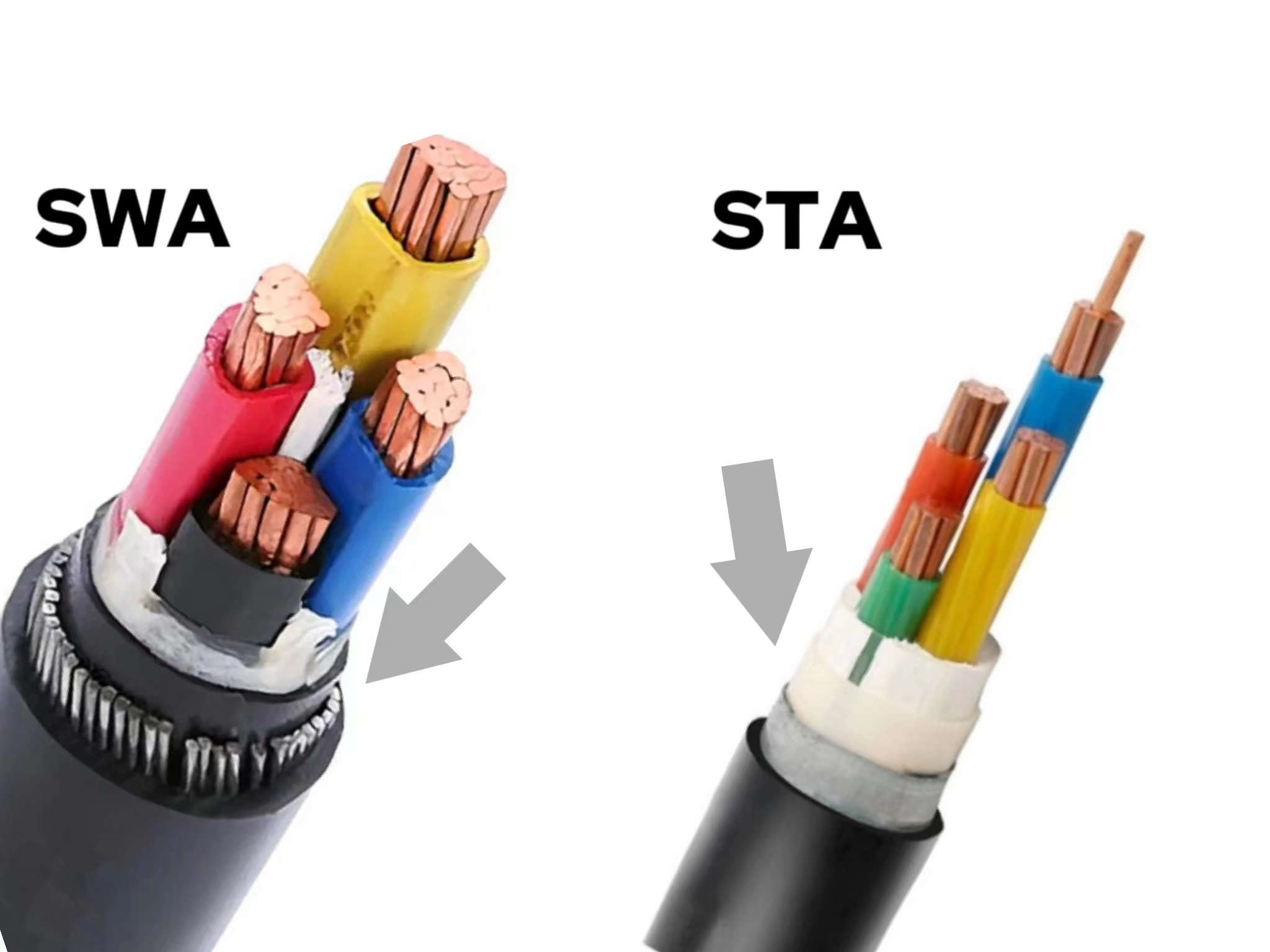

- XLPE Armoured Cable:A steel tape or wire layer gets added to the armor of XLP cables to provide extra strength and protection. This reinforcement boosts the cables’ resistance to physical damage.

- 11kv XLPE Cable:The purpose of 11kV XLPE power cables lies in the medium voltage distribution systems that operate at 11,000 volts. These conductors use XLPE insulation for superior electrical performance.

- XLPE Mv Cable:XLPE MV (Medium Voltage) cables are specifically built for medium capacity transmission, which averages between 1 kV and 36 kV.

- 33kv XLPE Cable:33 kV XLPE cables are used in energy-efficient long-distance power transmission systems at a voltage of 33 kV.

- XLPE Cu Cable:The XLPE Cu (Copper) cables have copper conductors paired with XLPE insulation.

- Single-Core XLPE Cables:Typically, single-core XLPE wire has one insulated conductor. This conductor is embedded in a protective jacket.

- Multi-Core XLPE flexible Cables: Rvv has multiple live conductor units in each insulated cable cover. These cables work well for systems transmitting power or controlling signals.

- Power XLPE Cables:XLPE power cables have capacity to send high-loading power over long distances. They’re formulated to handle maximum electrical stresses.

- Fire-Resistant XLPE Cables:Fire-resistant XLPE cables retain circuit integrity and electricity continuity during fires.

Aside from these, control cables and lszh cables are useful for transmitting quality signals and in safe confined spaces, respectively.

Conclusion

XLPE cables represent reliability, effectiveness, and eco-friendliness, ultimately forming future of electrical infrastructure. Since electricity enables homes, industries, and critical systems to run, XLPE cables are a crucial piece of the progress and connectivity we see now in our interconnected world.

Want to upgrade your electrical system using high-performing XLPE insulated cables? Reach out to ZW Cable to check out our custom XLPE wire offerings, XLPE cable pricing, and the potential for them to fully power your system.

FAQs:

1. Is XLPE Cable Water resistance?

It is important to note that XLPE cables are particularly sensitive to moisture. During the manufacturing process, if the insulation is contaminated with water, it can lead to a breakdown in the cable, significantly reducing its lifespan.

2. Why Is XLPE Such A Good Insulator?

XLPE has a crosslinked molecular structure. This molecular makeup gives XLPE better strength and ability to handle heat. The cross-linking mechanism got formed by this network of bonds. This mechanism boosts XLPE durability, heat tolerance, and electrical performance during electric use while shielding it from environmental damage.