Wires and cables are fundamental elements within the domain of electrical systems, serving as critical components that supply power to contemporary infrastructure, residence, and industry. Although they are frequently used interchangeably, they have different characteristics, so recognizing wire vs cable distinctions is vital. In this writing, we will provide a comprehensive examination of the diverse compositions, types, and applications of wires and cables, highlighting wire vs cable differences.

What is the wire?

A wire is a single conductor made of conductive material like copper or aluminum, usually cylindrical strand or rod of metal. According to the insulation condition, it is divided into two categories: bare wire and insulated wire. Electrical wires are ideal for straightforward electrical connections, transferring electrical current from one point to another, and are generally sold in spool or coil, 100 meters in a roll, wireless disk. Wires’ simplicity makes them ideal for a variety of basic electrical applications, from household wiring to intricate electronic devices.

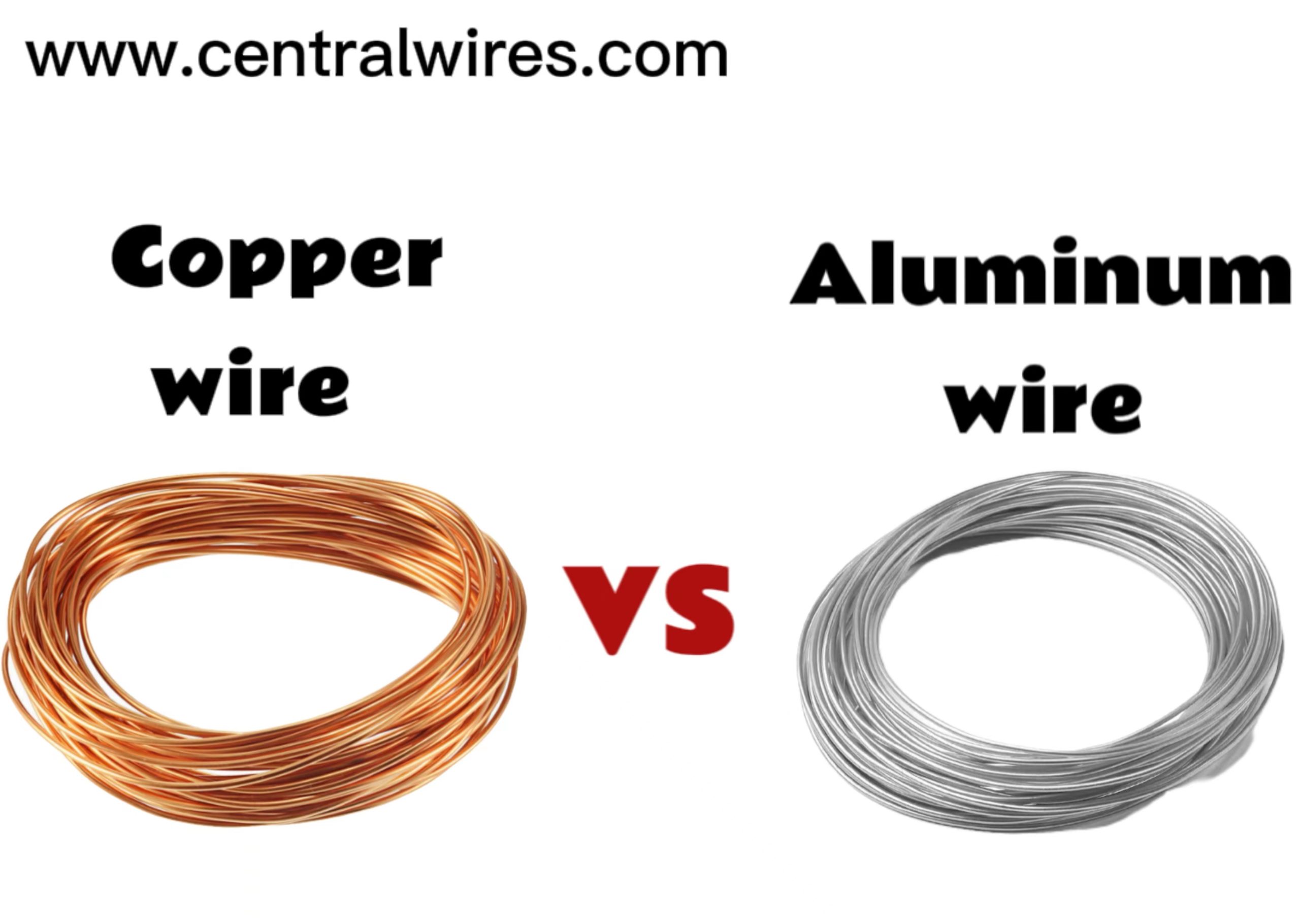

Moving beyond definitions, we now explore the material selection for electrical wires, which significantly impacts the performance and application of wires in electrical systems.

What are wires made of?

The choice of material for a wire depends largely on its intended use. Copper, known for its excellent conductivity and flexibility, is a standard in electrical wiring. Aluminum, while less conductive than copper, is lighter and used in power distribution. Some specialty wires are made of materials like silver or gold for high-conductivity needs, though these are less common due to cost. Additionally, there are steel, nickel, tungsten, and other alloys for specific applications that require high-temperature resistance or special magnetic properties. These wire materials can be used in combinations.

With that understanding of wires established, let’s shift to electrical wire types.

Types of electrical wire

To enhance comprehension of electrical wires, we present an overview of commonly encountered electrical wire types and uses.

- Twin and Earth Cable: Used for fixed wiring in residences for sockets, lighting circuits, and similar applications, it contains two insulated current-carrying conductors and an earth connector.

- THHN Wire: THHN stands for “thermoplastic high heat resistant nylon coated”; this wire is commonly used as building wire in residential, commercial, and industrial applications for its heat resistance, oil tolerance, and versatility.

- Speaker Wire: A low-voltage insulated wire that links loudspeakers and audio amplifiers. It features positive and negative poles to facilitate proper audio signal transmission.

- House Wire: Used for wiring in residential buildings, featuring PVC insulation for safety and available in various gauges for different applications like powering outlets, switches, and appliances.

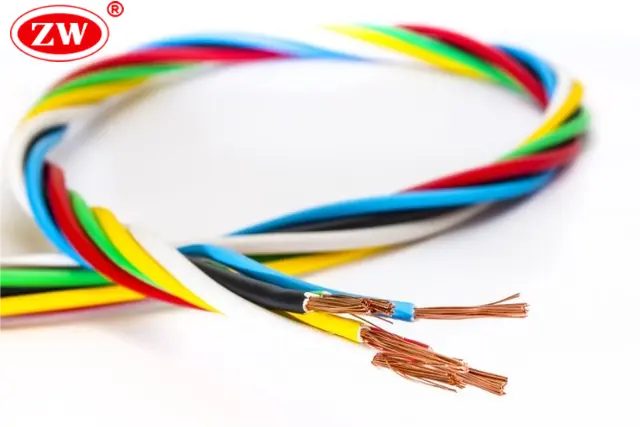

- Flexible Wire: This wire consists of multiple small strands braided together, offering high malleability for applications that require movement, like portable appliances and machinery.

- Screen Cable: or shielded cable, contains a metallic shield to protect against electromagnetic interference, ideal for use in industrial settings and sensitive electronic equipment.

After shedding light on the various types of wires, we now turn to the other focus of this article – cables.

What is the cable?

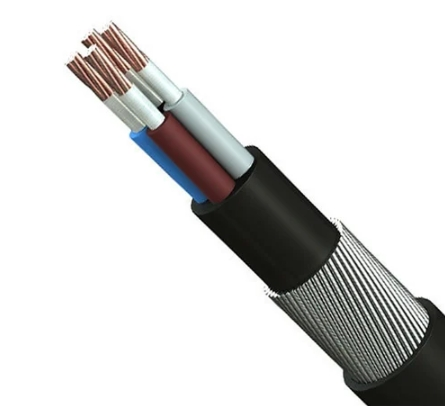

A cable is an assembly of two or more conductors that are twisted, wrapped, or bound together, each are individually insulated and wrapped within a protective outer sheath. Cables are designed for more substantial and protected transmission of power or data. They are essential in telecommunications, power distribution, and numerous other applications, particularly where exposure to the natural environment or extended reach are required.

Similarly, let’s have a look at the types of electrical cables. ·

Types of electrical cable

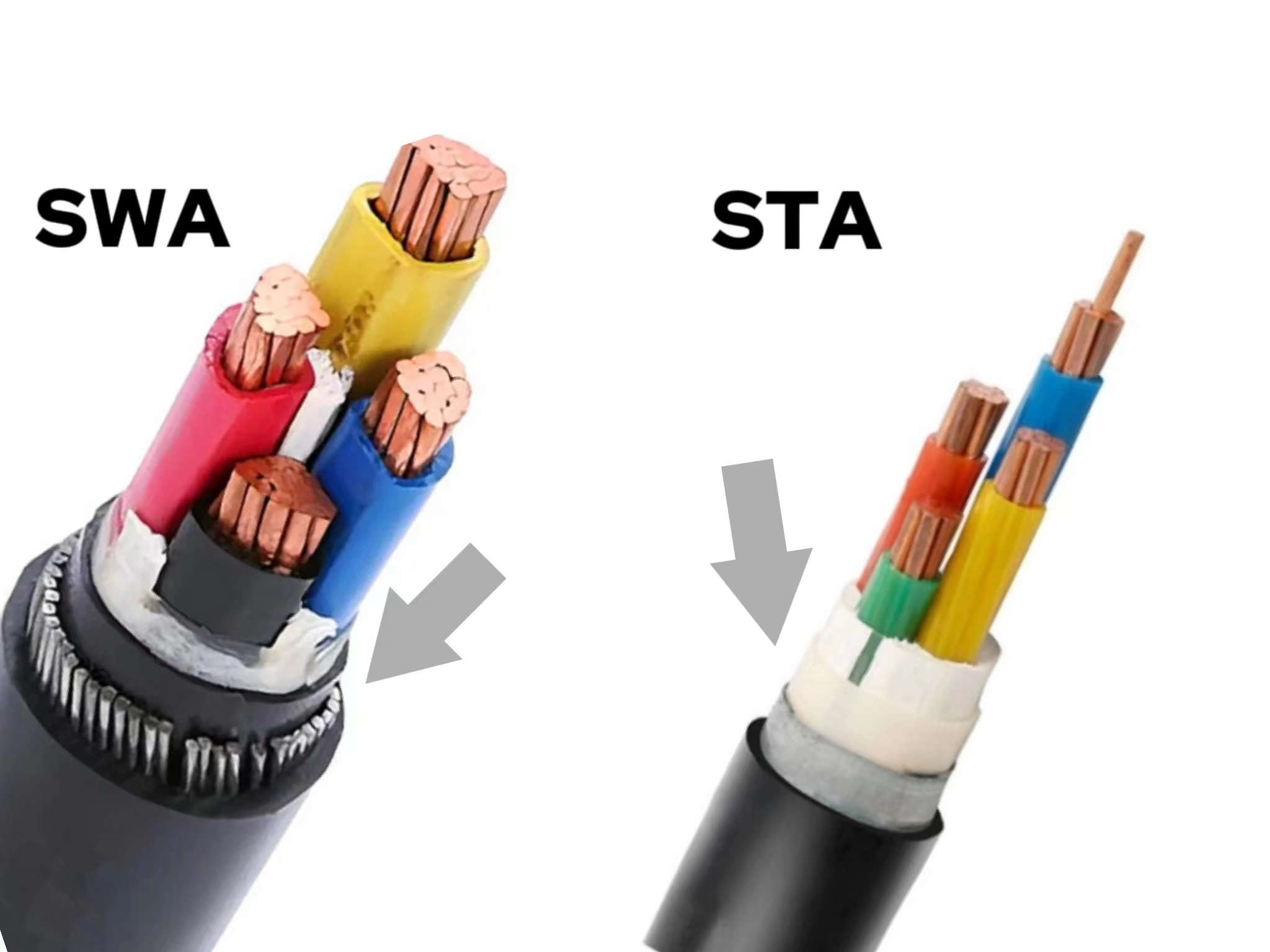

Cables can be divided into control cables, communication cables, power cables, and fibre optic cables according to their purpose, but what we have summarized are some of the most widely covered:

- Armoured cables such as steel wire armored cables (SWA) and steel tape armored cables (STA), are capable of withstanding high mechanical stresses and can be used in direct underground and outdoor applications.

- Low voltage cable (below 1kv) is often used for lighting and power wiring in both residential and commercial structures.

- Medium Voltage Cable is suitable for 3.6kV ~ 35kv industrial, public utilities, and other power distribution applications.

- Aluminum cables are a lighter and more cost-effective alternative to copper cables, they are typically used for overhead wiring and sometimes for wiring inside buildings.

- Rubber cables are highly flexible and ductile and are widely used in applications requiring resistance to extreme temperatures, abrasion, and tearing.

Grasping the different cable types gives us some idea about their applications. Following this, we present a detailed analysis of the distinctions between wire and cable.

Wire vs Cable

To fully understand the difference between wire and cable, we present a summary of five fundamental aspects, delineated in the accompanying table.

| 5 difference between wire and cable | ||

|---|---|---|

| Aspect | Wire | Cable |

| Construction | Simple, can be solid or stranded. | Complex, multiple insulated wires within an outer protective layer or sheath, with shielding or armoring on request. |

| Flexibility | Varies; solid wire is less flexible, stranded wire is more flexible. | Generally less flexible, but varies based on construction. |

| Durability | Less durable compared to cables, especially in harsh environments. | More durable, especially designed for harsh environmental conditions. |

| Function | Carrying electricity or signals, used in less demanding applications. | Used in demanding applications, can carry multiple data or power pathways. |

| Applications | 1.Electrical circuits and wiring systems. 2.Low-voltage power distribution. 3.High frequency application. 4.Internal connections in electronic devices and appliances. | 1.Power transmission in buildings and infrastructure. 2.Data communication in computer networks. 3.Control systems for machinery and equipment. 4.Audio and video signal transmission. 5.Instrumentation and sensor connections. Heavy industry and large-scale equipment. |

In short, the cables are high capacity, well insulated, and highly strength, but not as flexible and easy to install as wire. Additionally, It should be acknowledged that the distinction between wires and cables in reality is subtle, with many in the field referring to all electrical conductors colloquially as “wires. However, a general convention is that conductors with a cross-sectional area of 10 sq mm or more are classified as cables, while those below are termed as wires. Below, let’s take a look at the most basic division of wire and cable technology.

The most basic division of wire and cable technology is made on the basis of ?

The most basic division in wire vs cable technology boils down to the application, environment, voltage, and temperature, each of which plays a vital role in determining which wire and cable is used in a given situation.

- Different applications, such as power transmission, telecommunications, or data transfer, necessitate distinct types of wires vs cables, with the choice between them depending on the required capacity for conductivity, bandwidth, or data transmission.

- Environmental factors, including whether the installation is indoor, outdoor, or underground, further dictate the selection, as cables might be preferred for outdoor or underground environments due to their robustness and enhanced protective layers, while wires could be more suitable for indoor or controlled settings.

- Temperature considerations are also essential, as wires and cables must be capable of withstanding specific temperature ranges without compromising performance. In environments with extreme temperature variations, cables, often being more robust and better insulated, might be preferred over wires.

- Finally, the voltage levels guide the gauge and insulation selection: higher voltages typically require cables with thicker insulation and higher gauge numbers, while simpler wire configurations might adequately serve lower voltage applications.

This holistic approach ensures that the choice between wire and cable is not just a matter of preference, but a decision based on technical suitability and safety for the intended use.

Bottom Line

All in all, grasping the differences between wires and cables is vital for anyone involved in electrical system design, installation, or maintenance. Wire vs cable goes beyond simple preference and has a significant impact on the efficiency, safety, and reliability of an electrical system. Being familiar with the differences between wire and cable in terms of composition, type, and application can also provide a competitive advantage when selecting and purchasing. For those fumbling with the intricate details of wire versus cable, ZW Cable offers expert guidance and tailored solutions. Additionally, 12 gauge vs 10 gauge wire is available.