“LV cable” describes cables that function within a particular voltage range and serve as a connector between the distribution network and the power requirements of different devices. In our daily life, one of the phenomena we usually notice is that it becomes a popular choice for most people from lighting systems to Industrial electricity that runs continuously.

With the question in mind, we will analyze the reasons why low voltage cables are in the focus from different perspectives.

What is low voltage wire?

“Low voltage” provides the ability to supply power to a wide variety of equipment and systems while minimizing the risk of electric shock. Typically, the range is defined as not exceeding 1,000 volts for alternating current (AC) and 1,500 volts for direct current (DC). The categorization also determines cable design, insulation and installation requirements. More importantly, Let’s examine the specifics of its construction in more depth.

Construction of LV Power cable

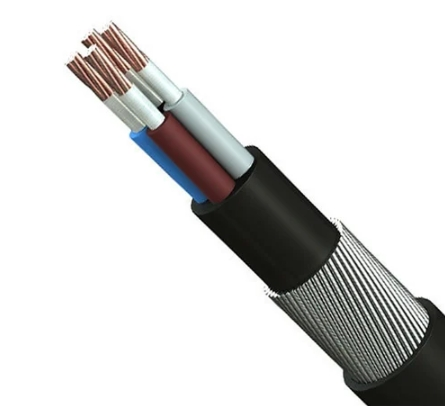

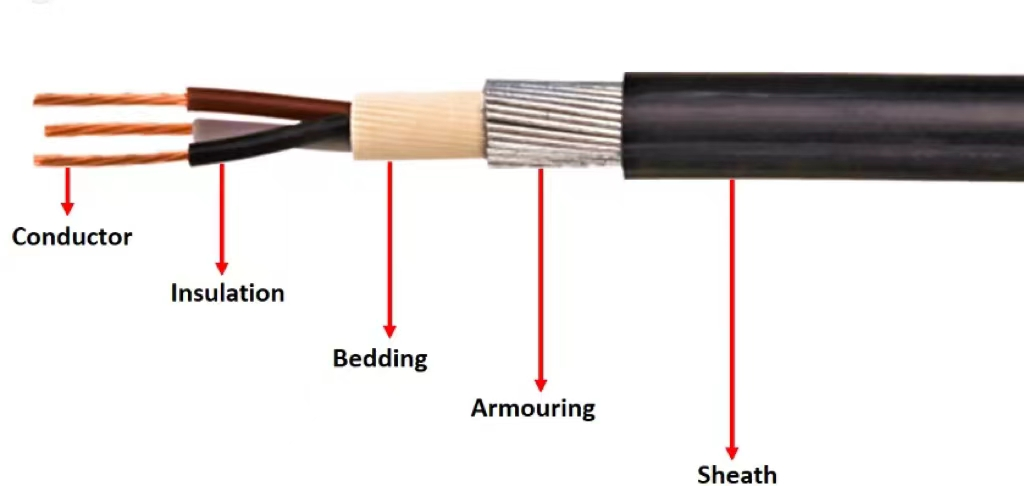

Usually, LV cables are made up of four components: conductor, insulation, protective sheath, and armor. Next, we understand the important role of each part in detail.

- Conductor: The conductor serves as the core of LV cable, tasked with the important role of transmitting current. low-voltage standard conductor material are usually made of copper or aluminum and are available in both stranded and solid forms.

- Insulation: Low voltage conductors wrapped in insulation. It is a non-conductive material that prevents leakage and keeps it Common materials used for low-voltage cable insulation include PVC (polyvinyl chloride), XLPE (cross-linked polyethylene) and rubber compounds. Each material has its unique properties; PVC is durable; XLPE has higher thermal and mechanical resistance; and rubber has excellent flexibility and resilience.

- Sheath: The outermost layer of lv power cable is called the outer jacket. It provides mechanical protection against abrasion, moisture, chemical contact and external forces. It also helps to improve the overall durability of the cable while assuring that it can withstand rigorous installation and long-term use in potentially harsh environments.

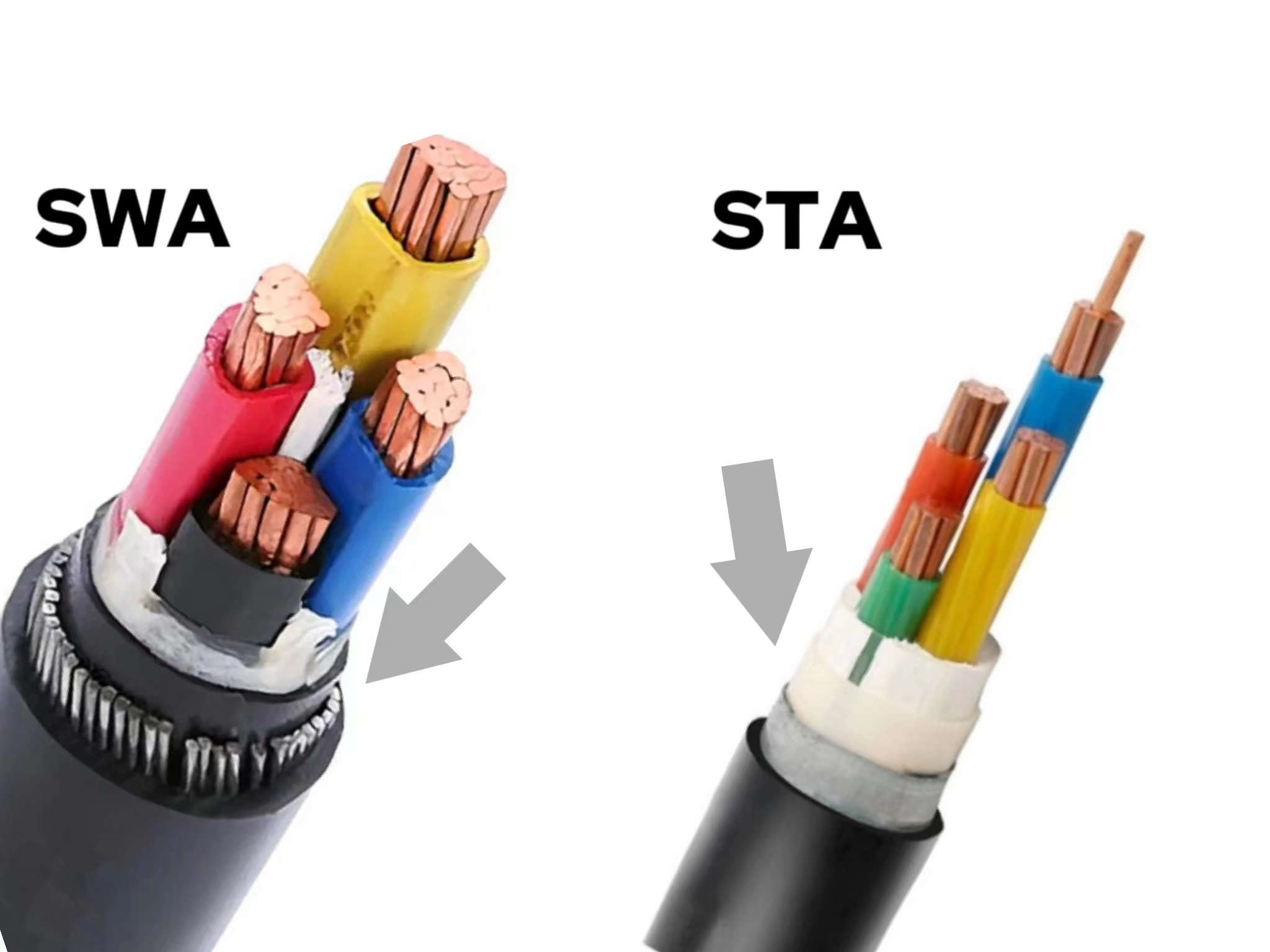

- Armoring: Although it is not necessary for every LV cable, extra armor is added for added protection to cables that are meant to be buried directly or in areas where mechanical damage is likely to happen. The wire used to make armor is typically steel or aluminum, which greatly strengthens the lv cable’s tensile strength while also shielding it from physical harm.

After discussing LV wire construction, one might be curious about how it differs from HV cable construction. Let’s dissect the differences according to their layout and uses.

Difference between HV and LV cables

In the long-distance transmission of electricity, we observe high-voltage cables carrying out important task; in the household or business sector, we observe again the flexible operation of low-voltage cabling. So there is a fundamental difference between the two in terms of voltage levels and uses.

- High-voltage cables are used to transmit electricity over long distances. Voltages are usually above 35 kilovolts. They have a rugged construction with multiple layers of insulation to withstand high voltages and prevent power loss. Therefore, they are an indispensable backbone of the transmission network.

- Conversely, low voltage power cables are used for AC voltages up to 1 kV and DC voltages sometimes up to 1.5 kV. Energy distribution in localized environments such as residential, commercial and industrial premises is more common. LV cable is simpler in construction and has less insulation than high voltage cables as they are designed for lower voltage levels.

The choice of high-voltage or low-voltage cables depends on the specific requirements of the distribution network, including transmission distances and end-use applications. When considering how and where to install LV cables, we need to go into detail especially in terms of burial depth to guarantee safety and durability.

How deep should LV cable be?

The right LV cable size plays a key role in the efficient operation of an electrical project. For example, 12 vs 14 gauge wire. similarly, the cable also needs to be of the right depth to be effective. The depth of burial of LV cables depends on a number of factors, including the type of soil, the presence of other utilities, and specific requirements that may be imposed by local codes. Next we can look at some generalized depths for lv cable in common locations.

- For typical low voltage cabling, it is usually recommended that they be buried at least 50 cm (approximately 20 inches) deep to avoid damage due to foreseeable disturbances such as gardening activities or minor construction work.

- In the case of utility services, it is important to ascertain that the LV cables are buried deep enough to prevent mechanical damage.

e.g.:

1. Public parks and open spaces are usually buried at least 45 cm (18 inches) ;

2. For agricultural areas, LV cable may need to be buried deeper than in residential areas, where it is typically 60 cm (24 inches);

3. The depth is usually greater for LV cables laid under roadways that are subject to the stress of vehicular traffic. Cables are usually buried at least 60 cm (24 inches) below the surface.

- In addition, we recommend that future extensions or upgrades be taken into account when burying LV cable. That way we can surely have adequate clearance from other utilities and protect the LV cables in a suitable conduit for easy access and maintenance.

What is worth noting is that for specific large-scale projects, it is best to call in a professional to determine the most appropriate depth based on the particular conditions of the site and the LV cable type being used. So what then should be taken into account when selecting the appropriate cable and wire?

How to choose low voltage cable?

The key to choosing the most appropriate low voltage wiring is to understand your electrical needs. Are you looking for a type that is easy to install or one that has a high level of safety? Remember it is a long-term endeavor, so choose wisely! We can focus our considerations based on the following aspects:

- Voltage Rating and Insulation

What cable specifics do we need to know before choosing a cable?

The focus concentrates on the equipment and the environment in which lv cable will be used to supply power. Taking the step is beneficial for selecting the appropriate voltage rating, insulation type and taking protective measures against environmental threats.

In the second place, we must accurately design the current and the maximum load capacity of the LV cable, which prevents the cable from overheating and keeps efficient operation. The current-carrying capacity of the selected lv cable must not only meet the maximum expected load but also meet the requirements for possible future power expansion or surge.

- Environmental Considerations

The installation environment is also a key factor in selecting the right lv cable.

Choosing the right insulation and sheath materials really depends on what they’ll go through, like how much they’ll be bent and stretched, if they’ll come into contact with chemicals, or if they have to handle really hot or cold temperatures. You’ve got options like rubber, PVC, and XLPE, and each one has its own strengths depending on the situation.

- Compliance and Installation

Keeping LV cable in compliance with applicable standards and laws is a further essential aspect.

As an illustration, consider adherence to industry-specific regulations and fire safety standards. By choosing a cable that meets the requirements, we are assured of a high degree of safety.

We also need to consider the physical aspects of low voltage power cable installation. Such as pathways, lengths and whether the cable will move or bend. Here are two common types of low voltage cables: stranded LV cable offer greater flexibility and are better suited to dynamic environments, whereas solid LV cables may be preferred for their structural integrity in static installations.

- Quality and Manufacturer

Finally, How do we choose a quality manufacturer?

For instance, ZW Cable is a prominent supplier of low voltage cables in the cable industry. It performs well in all types of electrical project applications. In addition, we also have a wide range of low voltage cables to suit different electrical needs.

LV Cable conclusion

Understanding LV cable in depth provides valuable guidance in the decision-making process. Moreover, we welcome any queries you may have regarding your specific cable purchasing requirements or selecting the appropriate type of LV cable. Please feel free to contact us if you would like assistance!

FAQs

1. What is the difference between MV and LV cables?

- MV cables for voltages up to 36 kV. They are used to establish the connection between the low voltage network and the main distribution network.

- LV cable systems are designed to operate at voltages up to 1 kV. It is mainly used to connect buildings and facilitate the transmission of electricity over relatively short distances.

2. Why are HV cables smaller than LV cables?

The primary distinction between high-voltage (HV) and low-voltage (LV) cables lies in their construction and insulation properties.

High-voltage cables are designed with multiple semiconductor and shielding layers, which significantly exceed the number found in low-voltage cables.

This additional layering results in a much thicker insulation for HV cables, contributing to a more complex structure overall. The enhanced structure and insulation are essential for safely conducting the higher voltages.