Reliable and efficient power supply is a requirement for people to use electricity safely, and XLPE cable can precisely fulfill the need. XLPE, as an advanced insulating material, is an indispensable part of the power infrastructure, helping us to better transmit and distribute electricity. We will explore xlpe power cable in depth to learn about it.

What is XLPE cable means?

The xlpe cable full meaning is cross-linked polyethylene cable, xlpe belongs to a kind of thermosetting material. Xlpe power cable refers to an electrical cable insulated with XLPE material that xlpe cable life expectancy can up to 50 years and thermal life of up to 40 years. Xlpe cable temperature rating is 90 degrees Celsius for long periods of time, and it can also withstand transient short circuit temperatures of 170~250 degrees Celsius and can operate from 0.6kv to 35kv. Xlpe greatly improves the heat resistance, current-carrying capacity and mechanical properties of xlpe wire ,reduces its shrinkage, so that it no longer melts after being heated, and maintains excellent electrical properties. Therefore, xlpe cable used for a variety of infrastructure projects such as lighting, hydronic heating and cooling, natural gas and pipeline laying. Then we will learn about the xlpe insulated power cable types.

XLPE cable types

Xlpe cable’s conductor is generally pure copper or pure aluminum, with xlpe as the insulation of the cable will have better electrical performance and mechanical properties, which makes xlpe insulated cable in both low voltage and high voltage system are widelu used. There are many types of xlpe insulated cables, the following mainly introduces the three xlpe power cable types can be learned.

Low voltage XLPE insulated cable

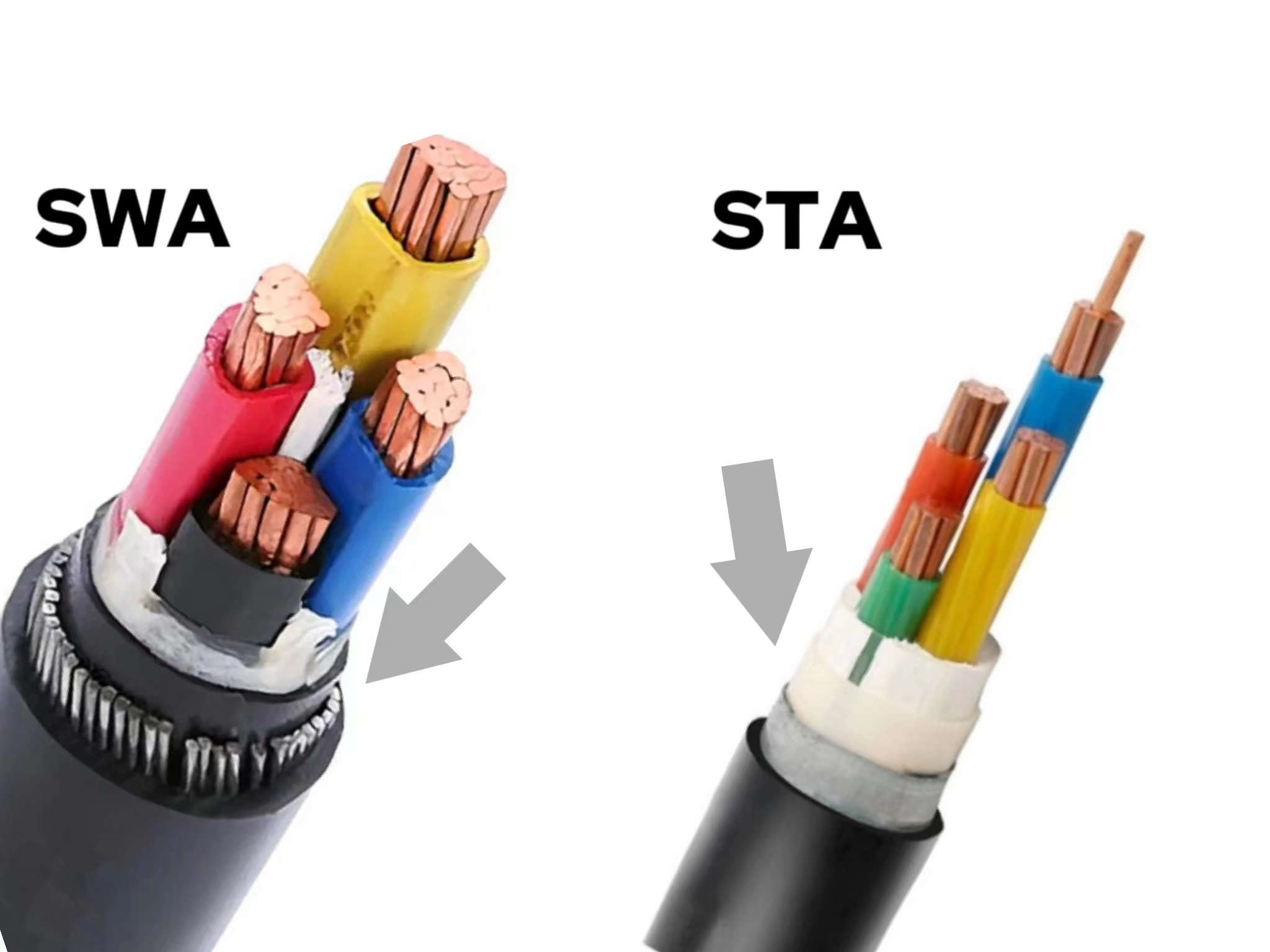

Voltage from 0.6kv to 1kv and using xlpe as insulation is known as low voltage xlpe insulated cable. Just like swa xlpe cable, it is suitable for low voltage power distribution and control systems in residential, commercial and industrial environments. Xlpe insulation offer higher current carrying capacity for low voltage cable, better thermal endurance, resistance and flexibility, and is manufactured in accordance with international standard to ensure the safety and stability of low voltage xlpe insulated cable.

Medium voltage XLPE insulated cable

The voltage range of medium voltage cable is 3.6/35kv, the use of xlpe insulation will make the xlpe mv cable have more excellent electrical properties. High dielectric strength, better thermal properties and best resistance allow medium voltage xlpe insulated cable not to be easily penetrated, maintain power stability under heavy loads, and have a more robust structure, last longer and reduce maintenance requirements and costs. Common sizes are 11kv xlpe cable and 33kv xlpe cable for power distribution in industrial plants, commercial buildings and utility substations as well as renewable energy projects. All medium voltage xlpe insulated cables must also meet the quality standards required by the industry to ensure their safety and reliability in use.

Read more about medium voltage cable

High voltage XLPE insulated cable

Voltages above 69kv can be collectively referred to as high voltage cable, and common high voltage cables include 132kv xlpe cable. xlpe high voltage cable has high dielectric strength and low dielectric loss, excellent thermal stability and resistance to the environment, and it is usually shielded and armored, which minimizes electromagnetic interference and reduces external damage caused by machinery. High-voltage xlpe insulated cables are used for long-distance power transmission, for connecting various parts of power stations and substations, including offshore wind power generation, and for the connection of high-voltage underground cables. The most important prerequisite is that xlpe hv cable must meet quality standards and be rigorously tested before sale to reduce risks and ensure its safety and reliability.

Learn more with high voltage cable

These are the three types of power cable xlpe, of course there are other cables that can use xlpe as insulation, but we should fully realize the advantages and disadvantages of xlpe cable, so as to make a proper choice for their own power equipment.

What are XLPE cable advantages and disadvantages?

For all kinds of power equipment, Xlpe cable has its pros and cons present.

Advantages of XLPE Cables:

- Thermal stability: xlpe insulated cable can withstand higher temperatures, and can work normally and maintain its electrical properties in high temperature environment;

- Current-carrying capacity: xlpe insulated cable is able to carry more electric current under the condition of suitable temperature;

- Dielectricity: xlpe insulated cables have good dielectric properties, will not be broken after bearing high voltage, can effectively transmit power, very suitable for high voltage cable;

- Resistance: xlpe wire have good resistance to chemical corrosion, humidity and mechanical damage, improving the environmental stress of xlpe power cables;

- Long service life:due to the various excellent characteristics of xlpe insulation, it makes xlpe armoured cable more reliable and safe, and also reduces the cost of people maintaining the xlpe cables.

Disadvantages of XLPE cables:

- Cost: xlpe insulation is generally more expensive, and xlpe cable manufacturing process is complex, which will increase people’s purchase cost and budget;

- Flexibility: xlpe cable is less flexible and cannot be bent at will, which requires more space for wiring;

- Weight:the size and weight of xlpe cable will be bigger and heavier compared with other types, which will consume labor and material resources;

- Repairability: xlpe al cable have limited repairs and require specialized knowledge and education. In some cases, damaged sections may need to be replaced altogether, resulting in higher maintenance costs.

Despite these disadvantages, cu xlpe cable is widely used due to their excellent electrical and mechanical performance. However, the specific requirements of the project must be carefully evaluated and these drawbacks taken into account when choosing the right type of al xlpe cable. Let’s then analyze the differences between xlpe and pvc cable.

PVC cable VS XLPE cable

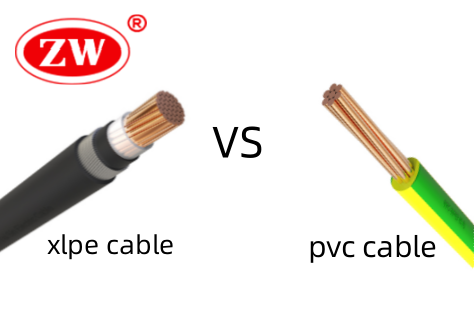

PVC and XLPE are two types of insulation types, there are some difference between xlpe and pvc cable as follow:

- Performance: xlpe wire has superior electrical performance than pvc cable, pvc is suitable for medium and low voltage system application, while xlpe is more suitable for high voltage system application;

- current-carrying capacity: in the case of pvc cable specification and xlpe cable specification are the same, xlpe insulated cable can withstand greater current-carrying capacity and more stable transmission of electricity;

- Heat resistance: xlpe power cable can withstand higher temperature than pvc cable without losing electrical properties;

- Flexibility: pvc cables are more flexible than xlpe cu cables and easier to wire in tight spaces;

- cost and budget: xlpe cable price is more expensive than pvc cable price, so in the low and medium voltage system, pvc cable is a more affordable choice; in the high-voltage system, xlpe power cable’s excellent electrical performance is worth people to buy;

The above is roughly a comparison between xlpe and pvc cable, to choose xlpe power cable or pvc cable, people should refer to the specific application and consider factors such as voltage, temperature, environment and cost. You can also consult a professional electrical practitioner to solve your electrical problems.

Conclusion

In summary, people have a better understanding of cable xlpe meaning, types, and advantages and disadvantages, and can better choose the right electrical solution for their application. Regardless of the type of electrical cable purchased, it is important to comply with standards, install it correctly and maintain it in a timely manner so that we can use the electric cable for a long time, safely and reliably to maximize its performance.

If there is a need to buy xlpe wire, you can research the xlpe cables market and analyze the xlpe cu cable more deeply. Of course, you can also consult ZW Cable, which can provide you with electrical solutions and can also be customized according to the specific requirements of customers, producing electrical wire and cable that not only meet the industry’s quality standards, but also at the right price.