From public areas to high fire risk areas, maintaining the integrity of our circuits is integral to the operation of system. That’s why we step into MICC cables!

Mineral insulated copper clad cables are one of the most common fire resistant cables. Its ability to withstand extreme temperature conditions guarantees the safety of important infrastructure. Let’s focus on understanding the operational MICC cable advantages and limitations to make a thorough consideration of your decision.

What is MICC cable?

Mineral Insulated Copper Cable overview

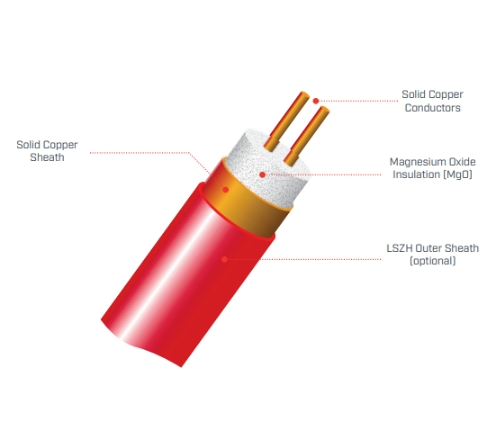

MICC stands for Mineral Insulated Copper Cable.Mineral Insulated Copper Cable is an example of Fire Resistant cable that neither releases toxins nor burns. In contrast to soft-skin polymeric cables, MICC is composed exclusively of two distinct elements: copper and magnesium oxide. The wire is extremely fire resistant and can be operated continuously in ambient temperatures up to 250°C.

MICC power cable uses a copper conductor core wrapped in a copper sheath with magnesium oxide powder as insulation to separate the conductor from the sheath. We can understand the fundamental structure of each part of cable offerings:

- MICC Cable Conductor: Constructed from stranded copper wires, it boasts excellent flexibility.

- Insulation Layer: Features an inorganic insulating material that’s resistant to high temperatures and non-combustible.

- Metal Sheath: The sheath consists of copper, copper alloy or stainless steel. It is specially treated to enhance its flexibility and can also be used as a grounding wire.

- Outer Sheath: It is made of low-smoke, non-toxic plastic with excellent corrosion resistance.

What is a MICC cable used for?

MICC cables are used in a wide range of application scenarios. In addition to their excellent performance in fire systems they are in fact essential for many applications, so what else can they be used for?

- Public buildings: MICC cables maintain the power and function of life-saving equipment such as fire alarms, emergency lighting and sprinkler systems, even under extreme conditions.

e.g. high-rise buildings, hospitals, schools, shopping malls, stations, airports, and other high-traffic areas.

- High-temperature places: In industrial manufacturing, machines often generate high temperatures. If the use of ordinary cables continue to run then it is likely that the service life is greatly shortened. The high melting point and chemical resistance of micc cables assure the continuous operation of motors, sensors and lighting distribution.

e.g. in refineries, chemical processing, metallurgical industry, steel industry, etc., where high temperatures are present in the distribution lines.

- Underground locations: MICC cables support signaling systems, power lines and communication networks. Their use enhances the safety and efficiency of underground public transportation services.

e.g. subways, underground warehouses, tunnels

In each case, the unique properties of MICC cables provide safety and durability by other traditional solutions.

MICC cable advantages and disadvantages

It can be observed that there are many examples of emergency systems failing in ordinary life. It is enough to show that the advantages and disadvantages of MICC cables must be carefully weighed to sesure the highest standards of safety and continuity of operation. For example, how many degrees of heat can the selected cable withstand? Are the micc cable sizes and specifications compatible with the electrical program? So with these questions in mind we focus on what are the benefits and limitations of mineral insulated cables.

Advantages of MICC cable

Strong Fire Resistance: MICC cables display exceptional fire-resistant qualities, making them ideal for environments where fire safety is paramount. Their construction keeps integrity even in extreme heat.

High Mechanical Strength: Designed to withstand rigorous conditions, cables possess high mechanical strength, enabling them to resist physical damages more effectively than standard cables.

No Aging: The mineral insulation and copper sheath of MICC cables prevent aging and a longer lifespan without degradation over time.

Corrosion Resistance: MICC cables are highly resistant to corrosion, making them suitable for use in chemically aggressive environments where other types of cables would fail.

Smoke-free and Non-toxic: In the event of a fire, MICC cables do not emit smoke or toxic fumes, enhancing safety by maintaining visibility and reducing risk to human health.

Disadvantages of MICC cable

Costs

First of all, before choosing a cable we usually compare micc cable prices to choose the right product.

MICC cables have a higher upfront cost compared to conventional PVC cables. If they are put to use in large projects, then the overall budget increases significantly. However, conventional cables need to be replaced and maintained at a later stage, so when you look at it this way, the cost of both is actually more or less the same.

Inconvenient installation

In addition, the ease of installation of MICC wires is something we need to consider in advance.

MICC cables are less flexible and more time-consuming to install than traditional cables. Therefore, it is more challenging to install in a small space. However, we can also choose the way of direct burial, which will save the cost of cable tray and improve the installation conditions.

Product Quality Control

Finally, despite the high quality and performance, it is unlikely that consistent quality control can be maintained across all manufacturers’ cable products.

The manufacturing process for MICC cables is very complex, involving precise materials and production standards. Any deviation in the process can affect the performance and safety characteristics of the cable. As a result, there is no shortage of cable manufacturers who, in the interests of profit, produce products with safety hazards. Therefore, when choosing a micc cable supplier, we must carefully select a quality company, for example, ZW cable, which is ranked among the top ten cable manufacturers in China, offers a series of products that have undergone rigorous testing.

How does MICC work?

The key to the operation of MICC cables is the utilization of copper and magnesium oxide, which are known for their non-toxicity and resistance to combustion. The core conductive copper is encased in a high-density magnesium oxide that can withstand temperatures in excess of 2000°C. It makes the MICC cables ideal for use in the most extreme conditions. Cable integrity and safety in extreme conditions.

The armored construction is wrapped in a copper jacket with a melting point of over 1080°C. MICC are the first choice for key circuits in emergency systems. They work reliably in fires and maintain the ability to operate at temperatures in excess of 1000°C without the need for additional protection such as polymers or tapes.

How to terminate MICC cable?

The termination and micc cable installation involves a very large number of tools and subtle techniques. Here, we provide a detailed and concise guide and a visual video at the end of this blog to help you with the complex issue:

Cutting the cable. We first need to cut the required length. A perfectly square cut facilitates precise installation.

Installing the shroud. If we decide to use the shroud, we will reverse it onto the cable to measure the length to be trimmed. After measuring, the shroud is placed over the cable in the correct orientation.

Removing the plastic cover. We should carefully mark the desired length of the tail on the plastic cover and leave a little extra length for the gland. Then use a sharp knife to carefully peel back the plastic to reveal the copper sheath underneath without causing any damage.

Peel back the copper sheath. Again mark the desired tail length on the cable and add a little extra length for the gland. We can use the stripping tool at this point to rotate around the cable while gently pushing forward to strip the copper sheath to the marked point.

Installing the Brass Can. Before positioning the brass can, I slide the gland assembly over the cable. Using a wrench to apply pressure, I rotate the brass can onto the cable, making sure it is tightly secured.

Seal and complete the end connection. Finally, fill the brass canister with sealant to keep there are no air holes and to avoid contamination.

The disk is then crimped into place to guarantee a tight seal. Slip the insulating sleeve over the wire, attach the gland to the junction box and tighten the nut.

If using cable coverings for protection in corrosive environments, cover any exposed copper or brass with protective tape. Finally, fit the gland shroud on for completion.

FAQs:

Is MICC still used?

Mineral Insulated Copper Clad cable has been the product of choice for fire rated cables since its commercial introduction in the 20th century. Its unique construction withstands extreme conditions and offers increased safety and reliability in fire-prone environments.

What is the lifespan of MICC cable?

Despite the higher cost associated with MLCC cables compared to conventional plastic cables, their primary advantage lies in their remarkable longevity. Numerous MLCC cables have been operational for up to 90 years. The durability is an important factor to consider, especially in applications where long-term reliability is essential.

MLCC cables contain no organic materials. It means that they are less prone to degradation over time, which is a common problem with traditional plastic cables.

Therefore, investing in MLCC cables saves money in the long term and reduces the number of replacements. It is the smart choice for infrastructures that require long-lasting performance.