There are a variety of options in data transmission and connectivity that can enhance the seamless operation of our digital lives. However, choosing the right signal cable is key to avoiding data loss or signal degradation over time.

In the post, we will delve into the unique features of quality signal power cables and how they compare to other options on the market, providing insight into making an informed choice for your communications needs.

What is a signal cable?

From the basic definition, signal wires are capable of transmitting data or electrical signals from one device to another. Signal cables are widely used in a number of fields, including the electrical engineering field and the medical field.

The core structure of a signal wire and cable consists of the conductor that carries the signal. The conductor is wrapped in an insulating layer to protect the integrity of the transmitted data. In addition, a shielding layer may be added to prevent interference from external electromagnetic fields and to improve signal clarity during transmission.

Types of the signal cable

Various signal cable types are utilized across applications, each designed to fulfill particular transmission requirements. Here, we will explore some of the prevalent signal cable varieties.

1. Coaxial Cable. Coaxial cables are capable of transmitting high frequency signals with minimal loss. Coaxial cables are constructed with a central conductor surrounded by insulation and a metal shield. They are widely used for television broadcasting, Internet connections and cable services.

2. Fiber Optic Cables. Fiber optic cables have better data transmission speed capabilities. They enable long distance transmission without electromagnetic interference. They are more used in telecommunication and high speed internet services.

3. Multi-core Signal Cable. Multi-core signal cables are indispensable in applications where multiple control signals need to be transmitted in a single cable. Consisting of multiple insulated conductors, multi-core signal cables offer versatility and efficiency for a variety of environments and applications, including industrial automation and building control.

4. Multi-core double shielded PVC cable. Multi-core double-shielded PVC cables feature a sturdy double-layer shield. They are suitable for sensitive environments as they provide excellent immunity to electromagnetic interference. The durable PVC jacket guarantees that the cable withstands the physical stresses, chemicals and temperature changes common in industrial and communications environments.

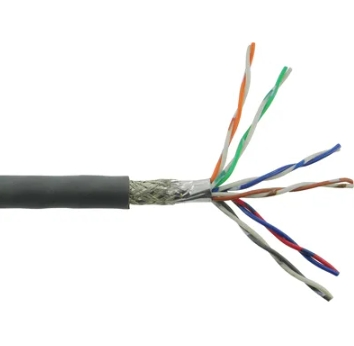

5. Multi-Pair Braided Cable. Multi-pair braided cables are suitable for environments requiring high signal integrity and EMI protection. The twisted pairs are configured within a common braided shield. Crosstalk and external interference are minimized. This type of cable is essential for precision data communication systems, audio applications and delicate electronic circuits.

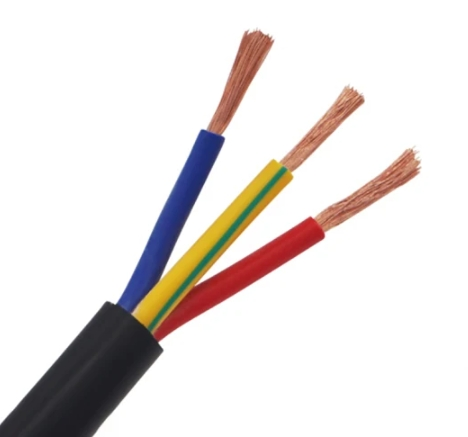

6. Semi-rigid PVC. Semi-rigid PVC cables combine flexibility and durability. They are easy to handle and install, especially in tight spaces. They are also resistant to environmental stresses such as abrasion. They are useful in control, instrumentation and power distribution applications.

Signal Cable vs Control Cable

Both control cables and signal cables are commonly used to transmit electrical signals, but many people find it confusing to distinguish between the two. So, what are the differences between these two types of cables in terms of their materials and applications?

Understanding the Differences in Material Composition

Signal cable outer negative shield. The shielding layer is generally conductive cloth, woven copper mesh or copper foil (aluminum), and the shielding layer needs to be grounded. This layer prevents interfering signals from entering the inner conductor to produce interference and reduces the loss of transmitted signals.

Control cables usually have multiple conductors. It is also possible to use a single cable for multiple control or power connections. Each conductor provides the necessary connections to control various aspects of the machinery, such as speed, direction, and mode of operation. Additionally, adding shielding to control cables prevents electromagnetic interference. However, we can choose whether to add it or not depending on the environment and the specific requirements of the project.

Understanding the Differences in Usage

The main function of signaling cable is to transmit signals. Signal cables are essential for everything from the transmission of various sensors and instrumentation to the connection of data communications over the Internet. In addition, signal power cables are very precise in their transmission, offering protection from electromagnetic interference and signal fidelity.

Conversely, the primary function of control cables is to connect equipment used for control or power. It is the workhorse of the electrical industry. They are commonly used to transmit electrical signals that control the operation of equipment and machinery in automation processes in industries such as construction and rail transportation. Therefore, control cables can carry higher currents and voltages as compared to signal wires.

However, a common question arises before we use them: Are control cables and signal cables interchangeable?

It is important to realize that control cables and signal cables are designed for different functions and are not interchangeable. Employing an incorrect cable type for a specific application can result in undesirable performance outcomes or potentially cause damage to the equipment.

How does a signal cable work?

Signaling cables work by transmitting data in the center conductor to achieve the transmission of electrical signals between devices. It has its own unique properties in terms of communication and data transmission systems.

At the heart of the signal cabling structure is the central conductor, which is primarily responsible for transmitting signals. The conductor is usually made of highly conductive materials such as copper or aluminum and can efficiently transmit analog or digital signals with minimal attenuation.

Around the central conductor, the signal cable has multiple layers of insulation and an outer metal shield designed to protect the integrity of the signal.

The insulation serves a dual purpose: it prevents physical damage while preventing direct mixing of signals from neighboring conductors within the cable. Meanwhile, the outer metal shield greatly reduces external electromagnetic interference (EMI), thereby improving signal purity from external noise. This comprehensive design enables reliable and secure data transmission in a wide range of applications and environments.

Conclusion

Signal cable is a key piece of equipment in electrical engineering. Whether they are used for personal or professional projects, the diversity of cable types and uses meets a wide range of needs. For those who are looking for a high quality signal cable company, ZW cable offers competitive signal cable prices and has the signal cable specifications to meet the various needs of your project. We welcome you to explore our product range on our website or reach out through email for inquiries on bespoke projects.

FAQs

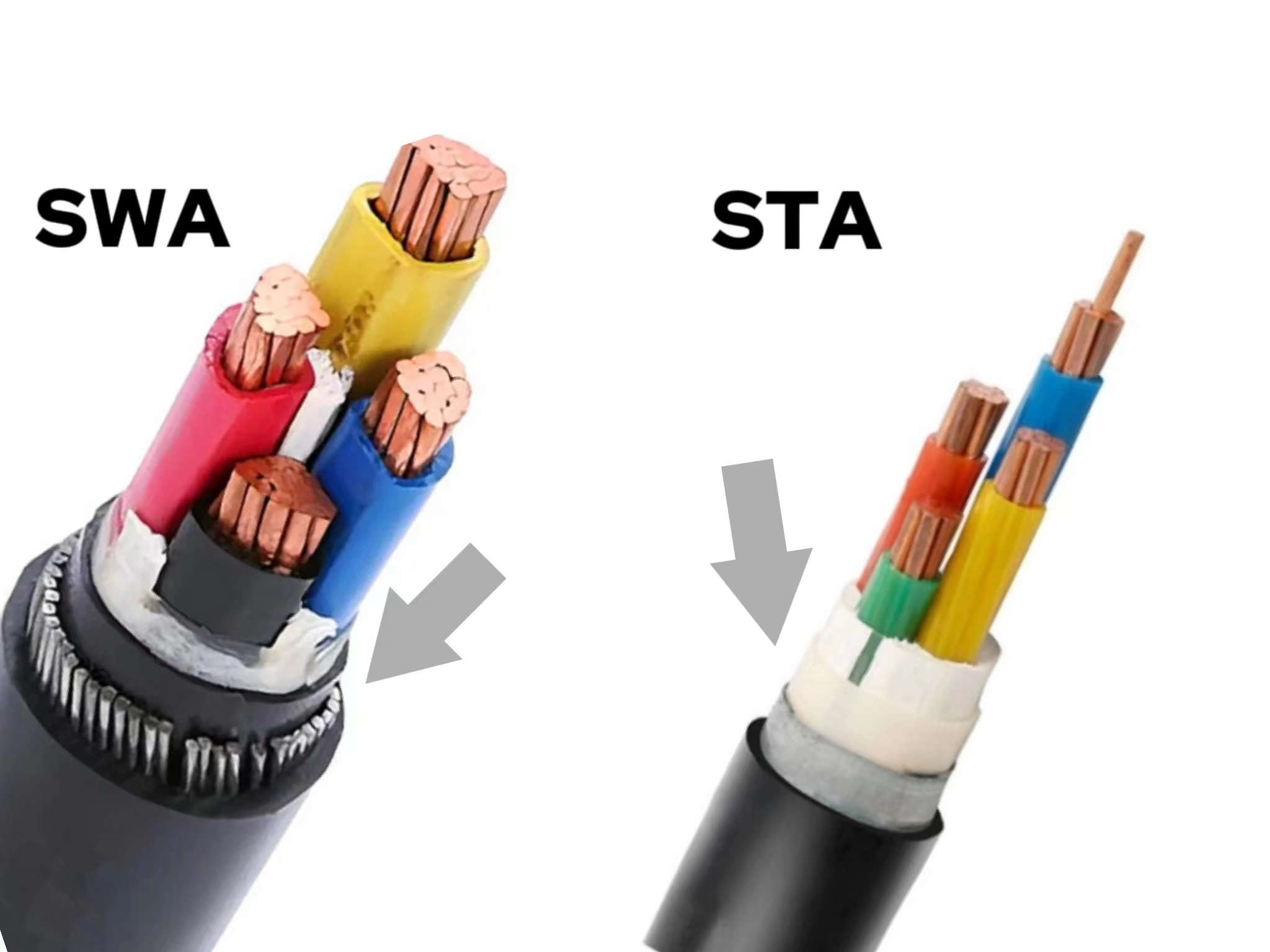

1. Difference Power Cables and Signal Cables

To help you decide between signal cables and power cables, we have provided you with more detailed comparison details:

- Difference in Function:

Signal cabling are primarily used to carry low-level electronic signals or data. They are the backbone of telecommunications. Long distance transmission of video and data is realized. In contrast, power cables are designed to conduct electricity and are an essential link in providing power to equipment, machinery and the entire electrical system.

- Different connection methods:

Signal electric cables connect equipment in a way that transmits data or signals. On the other hand, power cables are used to connect equipment or devices to the power grid to provide the necessary power to run tools, appliances and infrastructure.

- What about Carrying capacity?

Signal wires are designed to transmit electronic signals and have a low carrying capacity on their own. Power cables, on the other hand, are designed to carry higher currents.

2. What are the uses for signal cables?

Signal cables have a wide range of uses. Primarily, signal electrical cables are important connectors for audio and video equipment. It seamlessly transfers signals between devices such as televisions, computers, and game consoles. In addition, audio signal cables can be connected to speakers or headphones to amplify audio signals and enhance the listening experience from various media sources. It helps in transferring visual data from devices to computers or displays for editing or viewing.