Ever wonder what kinds of cables run behind the wall or power cables of your appliances? The major chances are that they might be PVC cables. PVC (Polyvinyl Chloride Cable) is easy to handle and PVC material provides good insulation to the main wire. This is why, you will see PVC in various applications.

But, here is the catch. You will find various types of PVC cables and manufacturers in the market today. So, it’s very important to consider the important factors while selecting the right PVC for your applications such that your PVC is durable, safe, and reliable to use.

So, in this business blog, we will see more about PVC insulated cable, its types, and the factors to consider while selecting the right PVC for any of your applications.

What is a PVC cable?

PVC cable, Polyvinyl Chloride cable, is a thermoplastic material that refers to an electrical cable with wire insulation or a jacket of cable. In today’s electrical industry, PVC insulated wire is considered a good material type for insulating applications as it has effective insulation properties with better strength and flexibility.

They do not have any chemical properties and are thus used widely in chemical industries.

The waterproof properties of PVC jacket cable make it suitable for extreme conditions. They can work effectively in any weather condition, making the liquids and gases to inset in the cable difficult.

All of these exceptional properties found in PVC have made it applicable in a wide range of areas. PVC insulated cable can be found in two categories:

Single-core wire and multicore cable.

Also Read: Single Core Cable VS Multi-Core: What’s The Differences?

Our PVC coated cables are available in two voltage types: 450/750V and 300/500 V. The conductors can be described as solid or stranded. You can find the conductor material in copper wire or tinned copper.

The major standards that PVC follows include- BS EN 50525-2-11, AS/NZS 5000.2, and IEC 60227. It ensures durable, and long-lasting cables for your needs.

Common Applications and Features for PVC Cable

Let’s see some common applications and features that make PVC cable everyone’s favorite:

Applications

- Residential Wiring

PVC cables are widely used in household electrical wiring. It is mainly used to supply power to outlets, and other household appliances.

PVC cables are reliable and safe, and you can easily hide them in your walls, making them a perfect choice for your residential wiring.

- Commercial Buildings

In places like office buildings and stores, PVC cables are used for both; fixed wiring and flexible installations. They can effectively handle all sorts of electrical loads and systems used in commercial buildings and keep your business running.

- Industrial Applications

Factories and machines are tough, and wires are no exception in those areas. That’s where the PVC cables come in. They can resist wear and tear and damage from oil and chemicals. Thus, PVC cables are suited for control cables in industrial machinery. The common type of PVC cable you will see includes flexible three-core cables.

- Underground Wiring

One of the exceptional characteristics of PVC cable is its strong resistance to moisture and chemicals. This property makes this PVC cable suitable for underground applications, including power distribution systems.

- Outdoor Uses

Whether it’s rain or shine, hot or cold, PVC can easily handle it. This is why, PVC cables are a great choice for many outdoor uses including construction sites, farms, and more.

- Automotive and Marine

The flexibility and resistance to vibration of PVC wire make it a perfect choice for automotive application areas. Similarly, its resistance to moist and salty conditions makes it a good option for marine environments.

Features

- Insulation and Jacketing Material

PVC materials are tough and resistant to moisture, providing double protection against environmental factors and electrical leaks. Thus, you can find PVC cables used as insulating and jacketing materials.

- Durable Insulation

PVC can resist oxidation, chemicals, and various weather conditions. This makes the cable more durable over time.

- Flexibility

The flexible nature of PVC wire makes the installation process easier, mainly in compact and surrounding areas.

- Fire Resistance

PVC materials are thermo-resistant, and some can even be self-extinguished. These properties of PVC add additional benefits to electrical applications.

- Chemical Resistance

One of the next best properties of PVC jacket cable is its chemical resistance. They can mitigate the impact of alkalis, acids, and other chemical effects.

- Moisture Resistance

PVC provides excellent protection against moisture, preventing the corrosion of conductive cores and maintaining insulation integrity.

- Cost Effective

As compared to other insulation materials, PVC is inexpensive, which makes it a cost-effective solution for a wide range of applications.

What are different type of pvc cable?

If you see the PVC cables, you can find the various types with various insulation thicknesses and with various unique designs. Let’s see some of the commonly found PVC cables in the electrical cable industry today:

1 Single-Core PVC Cables

These are the basic types of PVC coated cables with single conductors insulated with PVC material. The main feature of this cable type is its high insulation properties and good voltage capabilities. They are commonly used in power and lighting areas in both residential and commercial buildings. H05v-U is one of the common and major types of single-core cable in the cable industry today.

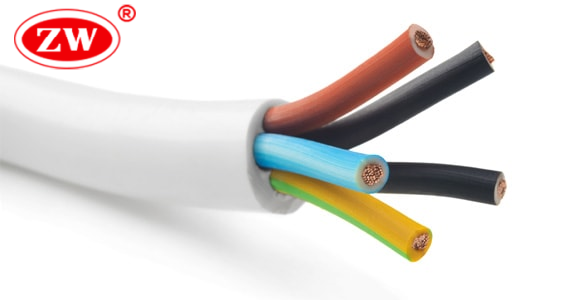

2.Multi-core PVC Cables

It consists of multiple conductors in a single PVC insulator. You will see the multiple conductors bundled in that single PVC insulator. This type of PVC cable is common in applications that require multiple signals and power paths. For example, you will see it in control systems, vehicles, power distributions, and more.

3. Flexible Cables:

Flexible pvc cables are super flexible and are made for constant movement and bending. They are mainly used in tools, machinery, and appliances that need to twist and turn frequently without getting damaged. You’ll often see them labeled as flexible cable 3 cores.

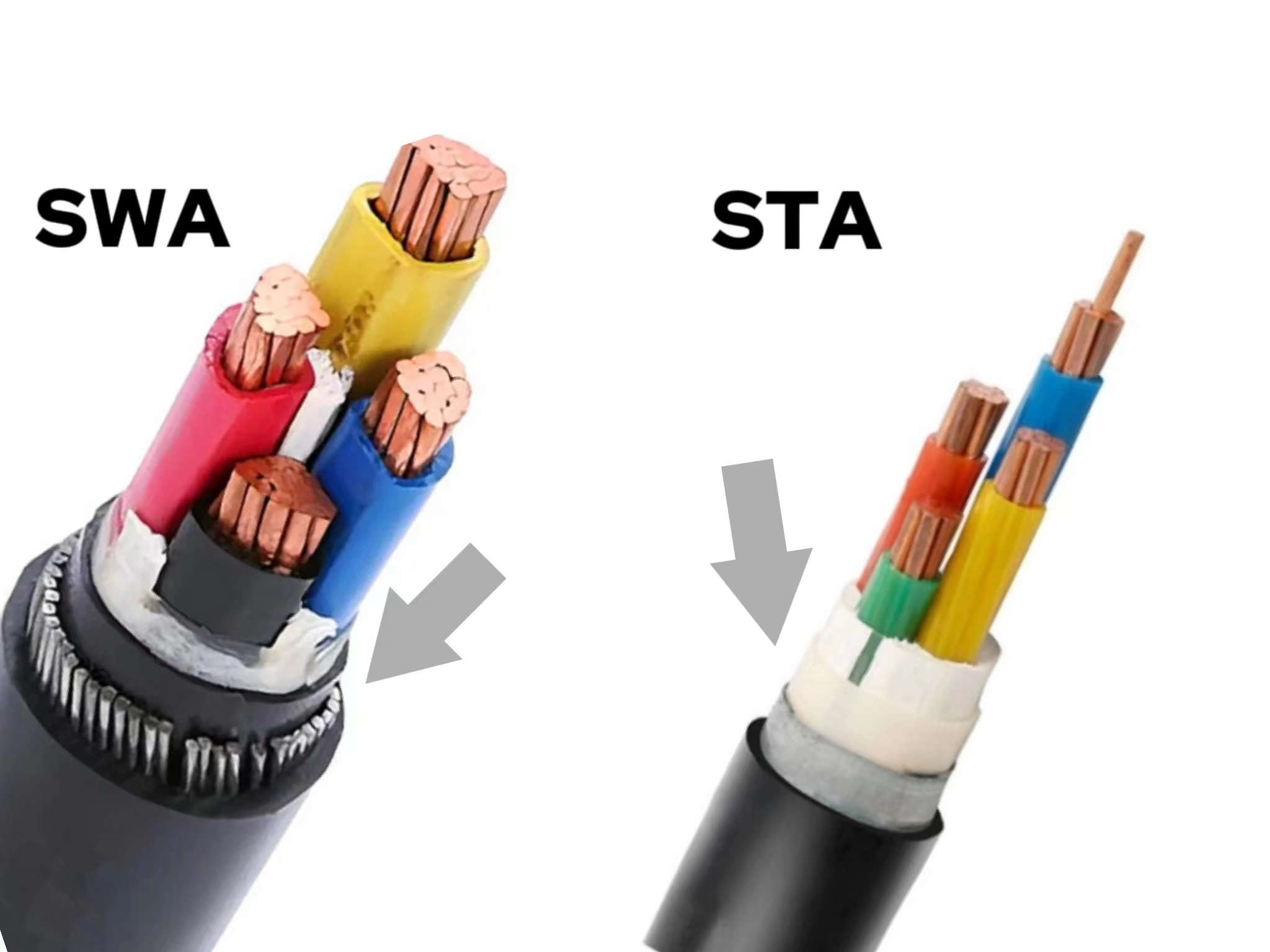

As the name suggests, pvc swa cable has an extra protection layer or say armor layer of galvanized steel wire. It makes them tough enough for outdoor use or direct burial. You can see pvc armoured cable in electrical power transmission lines with the name electrical power cables.

These cables have two insulated conductors for neutral and live wires. Besides, it also has an uninsulated earth wire within the PVC insulation. They are used for domestic wiring. Twin and earth cables come in various sizes. The most common type of twin and earth cable is used for socket circuits in the home. It has a size of 2.5mm

How to select PVC cable?

You need to consider several factors while selecting the right PVC cable for your application. Let’s see some of the common factors below:

1. Determine the PVC Cable Conductor Size

Before selecting the right PVC cable for your needs, always calculate the current capacity of your cable. Use the electrical load (in amperes) to determine the minimum conductor size required for your applications. Always follow the local electrical codes and standards for this step.

You need to select the cable with a larger conductor if you find out there is the possibility of increased load in the future.

2. Select the Right Specifications

Then the next factor to consider while selecting the right PVC cable is to include PVC sheath cable specification. It includes factors like length, area, copper diameter, and rated voltage. You need to verify that the conductor’s cross-sectional area meets your requirements. Also, ensure the rated voltage is matched.

For example, high-quality national standard PVC insulating cable, like BV 1.5 mm PVC, has a length of 100 meters per roll and a diameter of copper within the range of 1.36 to 1.38 mm.

You can contact ZW Cable, which can offer you proper guidance on cable specifications if you are unsure about it.

3. Check for Compliance and Certifications

No matter your application, always check for the cable’s certifications and compliance for your region. It includes CE marking, UL listing, IEC and ISO, and other indications of compliance with safety and quality standards.

Also, before installing the PVC cables, ensure that it meets the local code standards. These codes specify some important factors like conductor size, insulation types, and the ways to install the cables.

4. Consider PVC Materials

It’s important to consider the PVC insulation material, color, and flexibility while selecting the right PVC for your needs.

For example, high-quality copper is reddish purple and flexible compared to lower-quality copper with a rigid surface.

Besides, the insulation materials of PVC cable impact the longevity, and tensile strength of cable. Thus, consider the PVC material as the next important factor, as the material composition of PVC affects the durability and reliability of your cable.

5. Consider Mechanical and Physical Properties

Flexibility and durability are the next important factors to consider when deciding on PVC cables.

Flexibility is a crucial factor when your cable needs to bend often and will be in a dynamic environment. In such cases, you need to choose PVC cable insulation that can handle the frequent bending without cracking.

Similarly, durability is the next important factor when your cable is supposed to face abrasion and other mechanical stress. Estimate the mechanical durability of your application and ensure your PVC cables can withstand mechanical stress.

6. Find a PVC Cable manufacturer

It’s important to choose the right cable manufacturer with a proven track record of quality and reliability. The right manufacturer will not only provide you with a high-quality PVC cable but also excellent customer service and support.

For example, ZW Cable is the most experienced, certified, and reliable PVC cable manufacturer all over China. You can check their question-answer page to learn more about your questions on cable. Also, visit their product page to know more about their products and cables.

PVC Cable Conclusion

PVC cables are widely used in electrical applications. It offers the best insulating properties. They are widely used in residential, industrial, commercial, underground, and other applications.

So, while selecting the right PVC cables, you need to consider various factors as they directly affect the durability and reliability of the work.

If you are searching for the best quality PVC insulation cables for your project, then always remember the ZW cable. We have an expert team who is always ready to guide you through your difficulties. We manufacture and supply top-class PVC cables. So, no matter your project type, whether it’s small or big projects you can always trust ZW cables for the best cables.

PVC Cable FAQs

What are the IEC standards for PVC cable?

PVC cable follows the IEC standard 60227. Some of its further standards include:

- IEC 60173:1964:-It specifies the colors used for the cores of flexible cables and cords.

- IEC 60228:1978:- It defines the conductors used in insulated cables.

- IEC 60227-2:1979:-It outlines test methods for PVC-insulated cables with rated voltages up to 450/750 V.

- IEC 60332-1:1979:-It specifies tests on electric cables under fire conditions. It focuses on testing single, vertically insulated cables.

What is the difference between PVC cable and XLPE cable?

In the cable manufacturing industry, PVC (Polyvinyl Chloride) and XLPE (Cross-linked Polyethylene) are two commonly used cable insulation materials.

Let’s check out some of their common differences in below table:

| Aspect | PVC Cable | XLPE Cable |

| Flexibility | Inherently flexible, suitable for various uses. | Less flexible, but advancements improve installation. |

| Operating Temperature | Can operate up to 60 degrees C. | Can operate at temperatures up to 90 degrees C. |

| Electrical Prop. | Lower dielectric strength and constant than XLPE. | Higher dielectric strength, and provides better insulation than PVC |

| Cost | Less expensive than XLPE. | Typically more expensive than PVC. |

Which cable jacket is best for your application:- Pur vs. PVC cable?

Your choice between the PUR and PIR cable jackets should align with the specific needs of your application. For example, if you are dealing with a tough environment and a dynamic application, go for PUR cables, which provide effective flexibility and durability options. Besides, it has resistance to tears, impacts, oil, chemicals, and extreme temperatures.

While PVC insulation cables are less flexible and mostly applicable for stationary applications. They are budget-friendly with excellent electrical insulation, and they’re an ideal choice for indoor and less demanding situations. However, consider that PVC cables are prone to damage from chemicals and oil.