Power transmission networks in the complex field of electrical engineering depend heavily on the various types of high voltage cables and medium voltage cables. Hv cables are crucial for contemporary electrical setups, enabling the transmission of electrical power across vast spans. They play a vital role in ensuring the secure and effective distribution of electricity to homes, businesses, and industrial areas.

High voltage cables are classified according to their voltage handling capabilities. Cables within the medium voltage spectrum typically operate between 5 and 33 kilovolts (kV), while those in the high voltage category are designed for voltages exceeding 50 kV. This categorization is essential as it influences both the design and the specific use-case of the cables, especially electric cables employed in high voltage transmission lines. Such a classification system ensures the efficient distribution of power across varied electrical networks. This discussion aims to provide a thorough understanding of high voltage cables by examining their components, various types, and the critical factors involved in choosing the right cable for distinct applications.

Components of High Voltage Cables

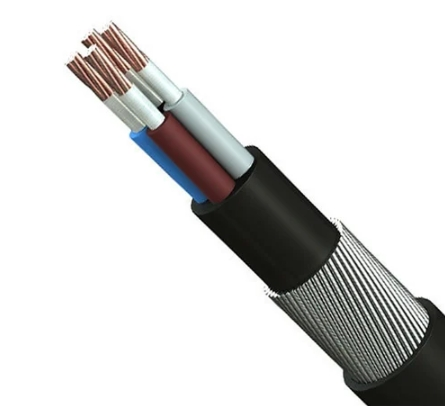

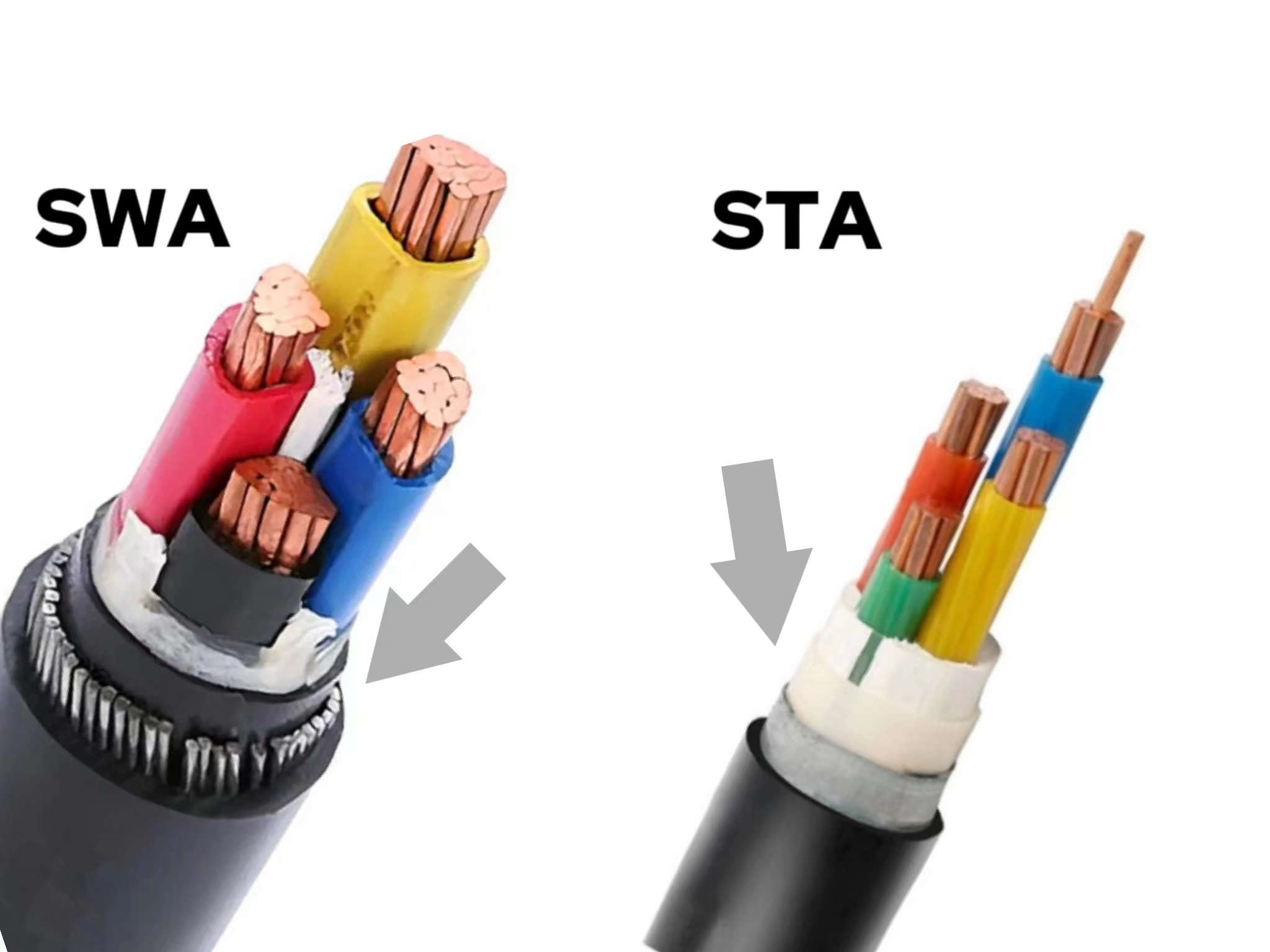

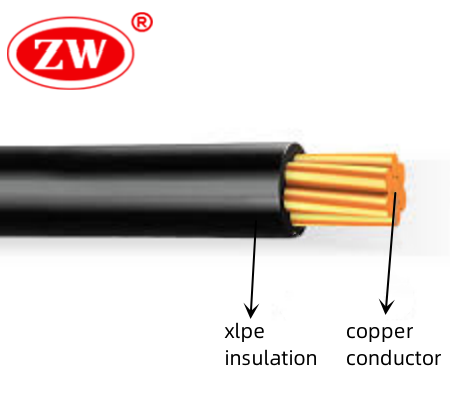

Each component of high voltage cable specifications plays a crucial role in their operation and safety. The conductor, typically composed of either copper or aluminum, is responsible for transmitting the electrical current. These conductors are vital in various high voltage power cable types and come in different styles such as compact, compressed, and sectored, each tailored for specific applications and current requirements.

Insulation is another essential element, often crafted from polymer materials like XLPE (Cross-Linked Polyethylene) or EPR (Ethylene Propylene Rubber). This insulation is critical, especially in medium voltage (mv) and high voltage wires, as it needs to endure extreme voltages while preventing electrical leakage. To enhance protection, these cables also include shields and a jacket. These layers defend against physical harm and environmental factors, thereby ensuring the cable’s durability and consistent performance. Now, let’s shift our focus to the different types of high voltage cables, each designed for specific scenarios.

Also read more about high voltage cables:High Voltage Cable: Everything You Need To Know

What are the different types of high voltage cables?

High Voltage (HV) cables are essential components in modern electrical power systems, engineered to manage substantial electrical stress and elevated voltages effectively. Selecting the appropriate HVDC cable type is crucial for maintaining operational efficiency and safety in power transmission projects. This overview of content provides an extensive overview of the primary high voltage cable types, each uniquely crafted to suit the diverse needs of various transmission environments.

1.Cross-Linked Polyethylene Cables: In the field of cable technology, the advent of Cross-Linked Polyethylene (XLPE) power cables marks a significant advancement. The cross-linking transformation of standard polyethylene significantly enhances its thermal capabilities, mechanical robustness, and chemical resilience. These advancements render XLPE cables exceptionally effective and dependable for a variety of uses. They are particularly well-suited for challenging applications such as high-voltage overhead lines, and for submarine and underground installations. Their resilience in harsh environments, combined with lower maintenance requirements and a prolonged service life, establishes XLPE cables as a superior choice for extended high-voltage transmission projects.

2. Oil-Filled Cables: Integral to the evolution of power transmission, oil-filled cables employ robust paper insulation infused with oil. This oil serves dual purposes – it insulates and helps in heat dissipation, enabling these cables to operate at higher capacities. Their utility shines in confined spaces such as underground and submarine installations, where managing cooling is challenging. However, these cables require more intensive upkeep, necessitating precise control of oil pressure and the maintenance of system integrity over their operational lifespan.

- Ethylene Propylene Rubber (EPR) Cables: EPR cables are characterized by their exceptional flexibility, which is a crucial factor in installations that require cables to bend around obstacles or in mobile applications. The ethylene propylene rubber insulation is highly resistant to a wide range of environmental stressors, including ozone and ultraviolet light, chemicals, and extreme temperatures. This toughness makes EPR cables ideal for demanding environments such as industrial sites, offshore platforms and other environments where cable performance is critical.

- Polyvinyl Chloride (PVC) Insulated Cables: PVC insulated cables stand out for their adaptability and functionality. The PVC insulation strikes a harmonious balance of efficient electrical properties and physical sturdiness. PVC cables boast resistance to oxidation, chemical influences, and various climatic conditions, rendering them apt for both indoor and outdoor use. Their cost-effectiveness and simplicity in installation have cemented their popularity in commercial and residential electrical setups. Nonetheless, it’s important to note their limitations in high-temperature environments, a key consideration in the cable selection process.

- High Voltage Flexible Power Cables: Specifically engineered for scenarios requiring both high flexibility and dependable performance under high voltage stress, these cables are a staple in industrial environments. They are crucial for linking large machinery, where enduring regular movement, bending, and vibration is essential. Flexible cables are designed with durable yet pliable conductors and advanced insulation materials. This ensures consistent performance and structural integrity even in the face of constant mechanical strain.

Every high voltage cable variant possesses distinct characteristics and specific uses, underscoring the importance of grasping these variances for their efficient deployment in power transmission. Recognizing the diversity among high voltage cables is a pivotal step, leading to the essential task of selecting the most suitable one that aligns with your specific requirements.

Choosing the Right High Voltage Cable

Selecting the appropriate high voltage cable is vital for maintaining safety, operational efficiency, and long-term durability in high-voltage applications. Consider the following essential criteria when choosing a suitable high voltage cable:

- Voltage Rating: Cables need to be appropriately rated to match the voltage demands of their intended application. Typically, high voltage cables are employed in settings where voltage ranges from 35 kV to 230 kV. It is crucial to select a cable whose voltage rating surpasses the highest voltage it is expected to handle.

- Current Carrying Capacity: The cable must be capable of handling the anticipated current load without the risk of overheating. This capacity depends on the conductor’s size, the insulation’s ability to withstand heat, and the environmental conditions of the installation.

- Environmental Factors: Cables are subjected to severe tests under different environmental conditions, such as chemical exposure, extreme temperatures and physical pressures. Therefore, we must be careful in choosing cables that can withstand specific environmental circumstances to ensure their long service life and functional integrity.

- Standards and Certifications: Ensure the cable meets relevant industry standards and certifications. For instance, cables used within the European Union often require CE marking. Such adherence to standards is a key factor in guaranteeing the cable’s reliability and effectiveness in its intended operational environment.

- Manufacturer and Supplier Reputation: When selecting a reputable manufacturer and supplier, it is imperative to opt for companies with a well-established reputation. Renowned brands such as Caledonian Cable and ZW Cables, along with prominent retailers like The Home Depot and Lowe’s, are recognized for their wide array of dependable and high-quality cable products.

- Custom Requirements: In instances where standard cables do not meet the unique requirements of a project, a custom solution may be necessary. Custom-designed cables can provide a tailored fit, ensuring optimal performance for specific applications.

The careful selection of high voltage cables, based on a comprehensive evaluation of voltage rating, current capacity, environmental factors, compliance with standards, manufacturer reputation, and custom requirements, is paramount. This meticulous approach ensures the optimal performance, safety, and longevity of the cable in its designated application, thereby supporting the integrity and efficiency of the electrical infrastructure it serves.

Type of High Voltage Cables Conclusion

The types of High voltage cable , which encompass both medium voltage cables and high voltage transmission cables, are indispensable to the framework of the electrical grid. Their significance extends beyond their basic function to include the intricacies of their design and the composition of the materials used in their construction. These cables, including specialized types like High Tension (HT) cables for high power transmission and solid underground cables for protected energy transfer, are meticulously engineered for optimal performance.

The selection of materials, from conductors to insulators, and the structural design of these cables significantly influence their efficiency and reliability. Understanding these aspects is key to informed decision-making in power transmission and distribution, ensuring not only efficient electricity delivery but also the highest safety and reliability standards.