Nowadays, electronic products penetrate into every aspect of people’s lives, and hook-up wire as the carrier of the connection, but also by people’s attention. Hookup wire can help people transmit data and power, and at the same time, people can also use hook-up wire for wiring low voltage and low current appliances. let’s get to know the following hookup wire meaning, insulation types, conductors and other knowledge now.

What is hook-up wire?

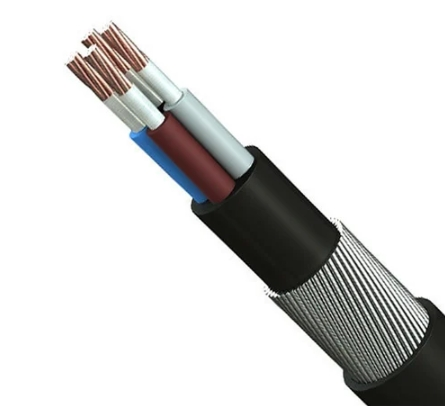

Hook-up wire, also known as lead wire, is a type of electrical wire that can be used for a variety of low voltage and low current applications. Most of the conductor is copper and tinned copper material; conductor wrapped insulation has many types, according to the different needs of people to customize. Insulation can prevent the hook up wire connected to the electrical appliances short-circuit phenomenon, for the conductor to provide a certain degree of anti-contact and mechanical protection. Our products such as 24 awg hook up wire, 18 awg hook up wire and 16 awg hook up wire are specially UL certified.

At the same time, in order to help better distinguish between different functional connections, the flexible hook up wire will have different colors, which can be applied to the circuit board component wiring, the connection between electronic devices, the wire hook up inside the appliance, as well as electrical wiring for automotive hook-up wire or a variety of electronic projects. After that, let’s take a look at the types of insulation available for hook-up wires.

Hook-up wire insulation types

Cable manufacturers use different hook-up wire insulation types to serve a variety of applications, and each type is matched to different appliances based on factors such as temperature resistance, flexibility, and environmental conditions. The main types of hook up wires insulation are listed below:

PVC (polyvinyl chloride): PVC is an effective wire insulation material that prevents the conductor from coming into contact with other conductive materials; it has excellent electrical properties, such as temperature resistance that allows the wire to withstand a wide range of temperatures; flexibility for easy bending of wiring; and moisture and chemical resistance. PVC is one of the most common used types of hook-up wire insulation and is found in a wide range of electrical equipment.

PTFE (Polytetrafluoroethylene): PTFE is a type of polymer that contains fluorine by carbon and fluorine atoms and has outstanding electrical qualities such as chemical resistance, thermal resistance, and nonstick, among others. Because of its low coefficient of friction and ability to withstand temperatures between -180 and 260 degrees Celsius, PTFE’s thermal stability can aid in the stability of the hook wire; The non-stick feature of PTFE ensure that the insulation will not attach to other materials, which can help hookup wires to retain the wire’s integrity over time. Furthermore, the exceptional durability and long service life of ptfe can reduce the frequency of wire replacement. Therefore, PTFE is also a type of hookup wire insulation.

XLPE (cross-linked polyethylene): its electrical properties make it a commonly used insulating material for hook wires. XLPE has strong high temperature resistance, can withstand high temperatures without reducing electrical properties, and can withstand 170-250℃ of the instantaneous short-circuit temperature; XLPE satisfies the standards of contemporary fire safety and environmental protection because of its great resistance to acid, alkali, and oil, and because its combustion products, which are primarily carbon dioxide and water, are less hazardous to the environment; XLPE insulation material is durable and wear-resistant, making xlpe hook -up wires more resistant to mechanical wear or friction; in addition, xlpe has a lower dielectric constant to help maximize the XLPE hook-up wires. Fire safety and environmental protection requirements; XLPE insulation is durable and abrasion-resistant, making XLPE hook up wire more resistant to mechanical abrasion or friction; in addition, xlpe has a lower dielectric constant, which is conducive to minimizing signal distortion in high-frequency applications.

FEP (Fluorinated Ethylene Propylene): Ideal insulation for hook-up wire, FEP has good electrical insulation properties that prevent leakage and maintain the electrical integrity of the electric wire. FEP insulation can withstand a wide range of temperatures, from very low to very high temperatures without noticeable degradation, and is highly resistant to a wide range of chemicals (including acids, alkalis and solvents) in environments where the hook-up wire may come into contact with corrosives. FEP also offers excellent resistance to moisture and humidity, reducing the risk of electrical shorts or performance degradation in wet conditions. FEP’s outstanding properties make it a popular insulation for hook up wire and lead wire.

Silicone rubber: It is a versatile material that can be used as an insulating material for hook-up wire and has unique electrical properties. Silicone rubber is highly flexible and can be twisted repeatedly when installing hook up wire; its flame retardancy reduces the risk of fire; it can withstand a wide range of temperatures, and its resistance to UV rays and radiation allows hook-up wire to be used outdoors; so in environments with stringent requirements for extreme temperatures and flexibility, people can choose silicone rubber hook-up wire.

These are the common types of hookup wire insulation, and one should choose them with respect to various aspects of the specific application, such as hook up wire current rating, hook up wire gauge, environmental conditions, and voltage rating. After that, let’s take a look at stranded and solid conductors of hook-up wires.

Hook-up wire stranded vs solid

The conductors of hook up wires can be categorized as stranded or solid, and both types can be used by everyone according to the specific requirements and characteristics of the application. Listed below are the main differences between stranded hook up wire and solid hook up wire.

- Flexibility: since the stranded hook-up wire is made of multiple tiny wires twisted together, it will be softer and more flexible than the solid conductor;

- Conductivity: in the same specifications, stranded wires have gaps in the existence of conductive properties than solid wires;

- Stability: solid wire is more stable, less likely to change the electrical characteristics due to changes in temperature or wiring.

- Cost: solid wire manufacturing process is not as complex as stranded wire, so solid hook up wire price is cheaper than stranded copper hook up wire;

- Environment: For harsh environments with high mechanical stress, stranded hook-up wire is more durable than solid wire.

The above points briefly describe the difference between hook-up wire stranded and solid, you make a choice, combined with the specific application and the required electrical characteristics to decide which is more suitable for use. Finally let’s look at hook-up wire for sale together.

Hook-up wire near me

The following alternatives are available to you if you need to purchase hook-up wire:

- online e-retailers: when making your purchase, you can choose online merchants like eBay, Amazon, or Alibaba, who will allow you access to a large selection of hook-up wire;

- electronics stores: you can search on a map for local electronics stores or hardware stores that usually sell hookup wire;

- wire and cable manufacturers and suppliers: if you have special requirements for hook wire, you can contact reliable wire manufacturers or suppliers. They can provide you with good hook-up wire and services;

Read More: Leading Top 10 Cable Manufacturers in the World

- Online search: you can search hook-up wire price on Google, and various cable websites will appear underneath, you can learn about them and then contact them online to buy or customize hook-up wire.

The above methods can be used for your reference, whether you buy hook-up wire online or offline, we hope you can buy according to the needs of your own application.

Conclusion

In a nutshell, you can get hold of relevant information about hook up wire such as hook up wire meaning, hook-up wire insulation types, hook-up wire conductors and hook-up wire near me. so that you can quickly make a correct choice for your appliances.

If you have strict requirements for hook up wire such as quality and durability, you can choose a wire and cable manufacturer that you can trust to customize it. ZW Cable is a reliable partner who can satisfy your diverse requirements and give you with a variety of cable solutions.