Control cables are the unsung heroes in the seamless operation of numerous mechanical systems, serving as critical links in industries ranging from automotive to aerospace. These cables ensure accurate and reliable transmission of control signals, making them essential in a vast array of applications. We take a deep dive into the world of control cable manufacturing, uncovering the expertise of leading control cable manufacturers, and looking ahead at emerging innovations and trends.

Leading Control Cable Manufacturers

- Bergen Cable Technology: With over 75 years of experience, Bergen Cable stands out in the realm of push pull control cable manufacturers. They specialize in both PUSH-PULL and PULL-PULL control cables, catering to a broad spectrum of applications with their seasoned expertise.

- Orscheln Products: Renowned for developing and manufacturing the Felsted™ and ACCO cable product lines, Orscheln Products boasts a diverse manufacturing capability. Their expertise extends from die casting and injection molding to stranding and extrusion, offering a comprehensive range of solutions.

- Cablecraft Motion Controls: Cablecraft is at the forefront of providing bespoke control cables, rod ends, ball joints, and linkage assemblies. Their application-focused approach ensures that customers receive not just products, but comprehensive solutions to complex challenges.

- Sava Industries: With over half a century of experience in push-pull cable assembly, Sava Industries has established itself as a leader in motion control cables. Their extensive experience aids organizations in achieving their production goals efficiently.

- Lexco Cable: Specializing in wire rope and cable manufacturing, Lexco Cable provides custom solutions for diverse industries, including aircraft and architecture. Their 8 core cable and 12 core cable are tailor-made for improved performance and easy installation.

- PR KABLE: As a leading control cable manufacturers in india, PR KABLE has over 40 years of experience in a wide range of applications. Their expertise spans from commercial to military applications, underlining their versatility and depth of knowledge.

- Elliott Manufacturing: Elliott’s Control Cables are known for their standard end fittings and built-in swivels that accommodate control arm movement. They offer a variety in series like 30, 40, 60, and 80, catering to diverse application needs.

- Tyler Madison: Tyler Madison specializes in custom push-pull control cables for industries like aircraft, medical, and automotive. Their expertise in cable design is tailored to meet the specific requirements of a wide array of applications.

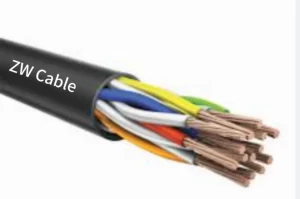

- ZW Cable:ZW Cable has established itself as a notable control cable manufacturer within cable industry. With a focus on producing yy cable and sy cable, ZW Cable caters to a diverse range of industrial needs, delivering solutions that are both reliable and efficient. Their commitment to innovation and excellence in cable manufacturing sets them apart, making them a go-to choice for those seeking dependable control cable products.

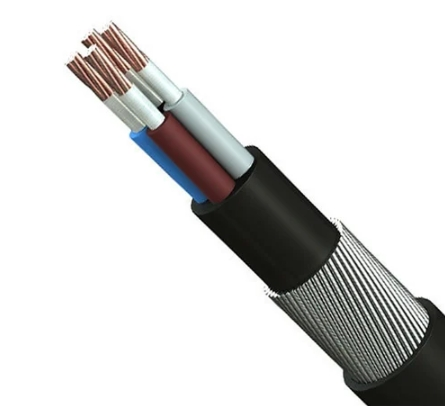

Control Cable Manufacturing Process

The manufacturing process for control cables is intricate and demands meticulous attention to detail to ensure the final product meets the highest standards of quality and reliability. Here’s an expanded view of this process:

- Material Selection and Procurement: The process begins with the careful selection of raw materials. High-quality metals like stainless steel, copper, or aluminum are chosen for their conductive properties and durability. The insulation materials, such as PVC or Teflon, are selected based on the application’s environmental and mechanical requirements.

- Wire Drawing: This involves reducing the diameter of the metal rods to the desired gauge through a series of drawing dies. The drawn wire is then annealed, a heat treatment process that enhances its ductility and electrical conductivity.

- Stranding and Conductor Formation: Multiple strands of the drawn wire are twisted together to form a conductor. This process improves the flexibility and strength of the cable, which is crucial for control applications that involve movement.

- Insulation and Jacketing: The conductors are then insulated to prevent electrical leakage and physical damage. Additional layers, such as shielding (for electromagnetic interference protection) and jacketing (for environmental protection), may be added depending on the cable’s application.

- Cabling and Twisting: Multiple insulated conductors are then cabled or twisted together in a specific configuration. This step is crucial for multi-conductor cables, ensuring they maintain structural integrity and flexibility.

- Testing and Quality Assurance: Throughout the manufacturing process, rigorous testing is conducted. This includes electrical tests for conductivity and insulation integrity, mechanical tests for tensile strength and flexibility, and environmental tests for temperature and moisture resistance.

- Packaging and Dispatch: The final product is carefully coiled, packaged, and labeled, ensuring it reaches the customer in perfect condition, ready for installation.

Development Prospects For Control Cable Manufacturers

The development prospects for control cable manufacturers are promising, considering the evolving landscape of technology, industrial automation, and infrastructure development. Here are some key factors that are likely to shape the future for control cable manufacturers:

- Growing Demand in Industrial Automation: The increasing adoption of automation in industries such as manufacturing, automotive, and utilities is driving the demand for high-quality control cables. These cables are crucial for efficient, accurate, and reliable communication between various parts of an automated system.

- Infrastructure and Urbanization: Rapid urbanization and infrastructure development, especially in emerging economies, are expected to boost the demand for control cables. These cables are essential in buildings for control systems, HVAC systems, and security systems.

- Technological Advancements: With the advent of smart technology and the Internet of Things (IoT), there is a growing need for more sophisticated control cables that can handle higher data rates and are compatible with advanced digital systems. Manufacturers who innovate in creating high-performance cables with enhanced data transmission capabilities will likely see growth.

- Energy Sector Expansion: The expansion of the renewable energy sector, including solar and wind power, requires robust control systems, thus increasing the demand for specialized control cables.

- Investment in Infrastructure for Electric Vehicles (EVs): The shift towards EVs and the subsequent need for charging infrastructure will likely create new opportunities for control cable manufacturers, particularly in developing cables for EV charging stations and related infrastructure.

- Regulatory Compliance and Standards: Manufacturers will need to stay compliant with international and regional standards, which might evolve to address environmental concerns, fire safety, and electromagnetic compatibility. This compliance is not just a challenge but also an opportunity for differentiation and value addition.

- Customization and Specialization: There is an increasing demand for customized solutions in control cables to meet specific industry needs. Manufacturers who can provide specialized, tailor-made products may find new market niches.

In summary, control cable manufacturers who focus on innovation, adaptability, and compliance with global standards are likely to experience significant growth and expansion in the coming years. The key will be to anticipate and respond to the evolving needs of industries that rely heavily on control and automation systems.

Conclusion

The world of control cables is a testament to the intricate blend of engineering precision and practical functionality. The manufacturers profiled here are not just producers of cables; they are innovators and pioneers, constantly pushing the boundaries of technology and application. As industries evolve and new challenges arise, the role of control cables and their manufacturers will continue to be pivotal. Their ongoing commitment to quality and innovation ensures that control cables will remain indispensable in powering and controlling systems of tomorrow.

Related Post:

1. 10 Leading Electrical Cable Manufacturers In The World

2. 7 Outstanding Electrical wire manufacturers in the world

3.Leading Top 10 Cable Manufacturers in the World

4.10 Leading Electrical Cable Manufacturers In The World

5. 7 Outstanding Electrical wire manufacturers in the world

6.7 Leading Thhn Wire Manufacturers

7.Global Leaders Medium Voltage Cable Manufacturers In World