Insulated copper wire emerges as a fundamental component, integral to both everyday appliances and large-scale industrial machinery. This article aims to provide a thorough understanding of copper wire insulation, unraveling its essential role, varied applications, and the nuances of its construction. We will delve into what sets this type of wire apart, its conductivity properties, the process and importance of insulation stripping, the types suitable for recycling, its market value, and where to procure it. By the end of this exploration, readers will gain a comprehensive view of copper insulated wire, highlighting its significance in the modern electrical landscape.

What is Insulated Copper Wire?

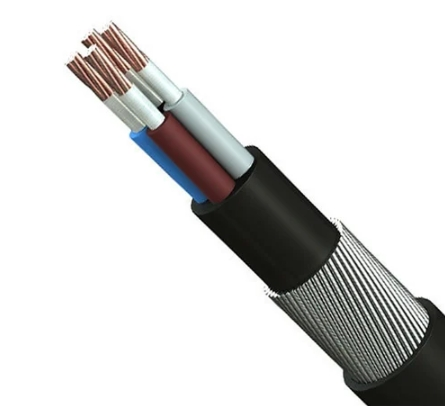

Copper wire with insulation is a specialized type of electrical wire that plays a pivotal role in conducting electricity. The core is composed of a copper conductor, renowned for its excellent electrical conductivity, wrapped in an insulation material. So it can be used for electromagnetic fields in the same way as mineral insulated cables. While this insulation serves to prevent electrical hazards such as electric shocks and short circuits. Insulation is typically composed of materials such as rubber, polytetrafluoroethylene (PTFE), or polyvinyl chloride (PVC). We can further explore the types of insulation materials:

PVC Insulation: Polyvinyl chloride, a widely adopted insulating material, is favored for its flexibility, cost-effectiveness, and durability, making it a versatile choice in various electrical applications.

Rubber Insulation: This material is characterized by its outstanding flexibility and is particularly suited for environments where high elasticity and robustness against physical stress are required.

Rubber Insulation: This material is characterized by its outstanding flexibility and is particularly suited for environments where high elasticity and robustness against physical stress are required.

Teflon Insulation: Employed in high-performance and advanced electrical applications, Teflon (PTFE) is renowned for its exceptional heat resistance and ability to maintain insulation properties under extreme temperature conditions.

Teflon Insulation: Employed in high-performance and advanced electrical applications, Teflon (PTFE) is renowned for its exceptional heat resistance and ability to maintain insulation properties under extreme temperature conditions.

Every type of insulation has its special qualities and is selected according to the specific requirements of the application. In addition, we can dissect more information about copper cables about whether copper wire is a conductor or an insulator.

Every type of insulation has its special qualities and is selected according to the specific requirements of the application. In addition, we can dissect more information about copper cables about whether copper wire is a conductor or an insulator.

Is Copper Wire a Conductor or Insulator?

Copper wire serves as an effective electrical conductor, which contributes to its widespread utilization in electrical wiring applications. Its exceptional electrical conductivity arises from the specific atomic structure of copper, which allows free electrons to traverse through the material with ease. This property enhances the seamless propagation of electric current, marking copper wire as an indispensable element in the realm of electrical conductors.

When copper wire is utilized in electrical applications, it is often wrapped in rubber or polyvinyl chloride (PVC), an insulator that makes sure the current flows in the correct direction. Although the copper wire itself is a conductor, the insulating material surrounding it is an insulator. However, sometimes we strip copper insulation for our needs, so how do we do that?

How to Strip Insulation from Copper Wire?

The process of stripping insulation from copper wire is a critical step in recycling and electrical work. This can be done using manual tools or automated machines, depending on the scale of the operation.

On the one hand, Machine wire strippers are a more suitable choice if they need to be used in large-scale operations to increase efficiency, such as large scrap recyclers, which can handle large quantities of scrap wire more efficiently. These machines work quickly to safely strip insulation and flatten it immediately.

On the other hand, If in precision work, we can use hand tools, so we can take subsequent steps if we employ tools for manual stripping:

Step one: Get the Right Tools

The most common tool for this job is a wire stripper. This tool comes with different sized slots to accommodate various wire gauges. A utility knife can be used in place of a wire stripper if you don’t have one, but more caution is needed to avoid cutting or harming the wire.

Step two: Secure the Wire

You can use a vice to hold it in place if it’s not already stable. Take care not to clamp the wire too firmly since this could harm the copper.

Step three: Score the Insulation

If you’re using a wire stripper, choose the slot that matches the gauge of your wire. Insert the wire and squeeze the handles together. This should cut through the insulation without damaging the wire. If you’re using a utility knife, gently score around the circumference of the insulation. Be careful not to cut too deeply and nick the wire.

Step four: Remove the Insulation

You should be able to slide the insulation off the end of the wire after scoring it. A mechanism to remove the insulation may be built into the wire stripper if you’re using one. If not, you can remove the insulation with pliers or your fingers.

The process of removing copper insulation layers not only recovers valuable copper, such as one of the most common types sold to waste product depots:#1 insulated copper wire, but also reduces waste and protects copper resources if properly recycled. But remember that safety is always the priority when using tools and wires. Always wear protective equipment and work in a bright, stable environment. Additionally, you need to figure out what can be salvaged from copper insulated wire before removing the insulation.

What Types of Insulated Copper Wire Can You Scrap?

The types of insulated electrical wire that are commonly scrapped include:

Thin Insulated Wires: Found in electronic devices and small appliances.

10 Gauge Insulated Copper Wire: Used in larger electrical systems, offering a balance between flexibility and strength.

Insulated Solid Copper Wire: Common in residential and commercial buildings.

From a waste management and recycling perspective, copper is one of the most precious metals due to its inherent recyclability. Given its capability to be repurposed and reutilized, copper continues to be recycled as long as novel applications emerge. Scrap electrical wire price is notably influenced by their copper content, with higher copper composition commanding increased value in the recycling market. In addition, the difficulty of removing the insulation layer affects the value of the waste. Therefore, we also need to have a look at the price for insulated copper wire.

How Much is Insulated Copper Wire Worth?

The valuation of insulated copper cables on the scrap market is influenced by a number of factors. These include the purity level of the copper and broader economic factors such as global market trends. Here are some of the key determinants:

Copper Content: The amount of copper contained in the wire significantly impacts its value. The thicker the wire and the higher the percentage of copper it contains, the more valuable it will be.

Purity and Condition: The quality of the copper determines its worth in the recycling market. In general, coated copper wires composed of pure, unalloyed copper are worth more than those made of inferior copper.

Market Fluctuations: The dynamics of supply and demand in the international market(LME) have an impact on the price of copper wire with insulation, just like they do for any commodity. Shifts in the manufacturing sector and general global economic trends are just two examples of economic factors that can significantly affect the value of insulated copper wire scrap.

As our plant disposed of a shipment of scrap cable in October, it noticed that insulated copper wire ranges significantly in price, usually from $4.50 to $6.20 per kilogram, this depends specifically on the factors mentioned above. However, for the most accurate and current pricing, it’s best to check with local scrap metal dealers or recycling centers, as they can provide the latest market rates. Remember that they will need to process the wire to remove the insulation and extract the copper, so the price offered will be less than the market rate for pure copper.

As our plant disposed of a shipment of scrap cable in October, it noticed that insulated copper wire ranges significantly in price, usually from $4.50 to $6.20 per kilogram, this depends specifically on the factors mentioned above. However, for the most accurate and current pricing, it’s best to check with local scrap metal dealers or recycling centers, as they can provide the latest market rates. Remember that they will need to process the wire to remove the insulation and extract the copper, so the price offered will be less than the market rate for pure copper.

Where to buy Insulated Copper Wire?

When buying insulated power cables, it’s important to consider the specific requirements of your project. Suppliers offer a range of options, from heavy-duty power cables to finer wires for electronics. Factors such as insulated copper wire size, insulation type, and overall quality should be considered alongside the price to ensure the best value for money. Typically, the following channels allow us to obtain products:

Specialty Electrical Stores: These are specialized stores that focus on selling electrical components and equipment. As an illustration, Toolstation、Hunddersfield, they can offer a wide selection of wire types and gauges.

Online Marketplaces: It is capable of offering a wide array of options at competitive prices. For example:Amazon and Walmart.

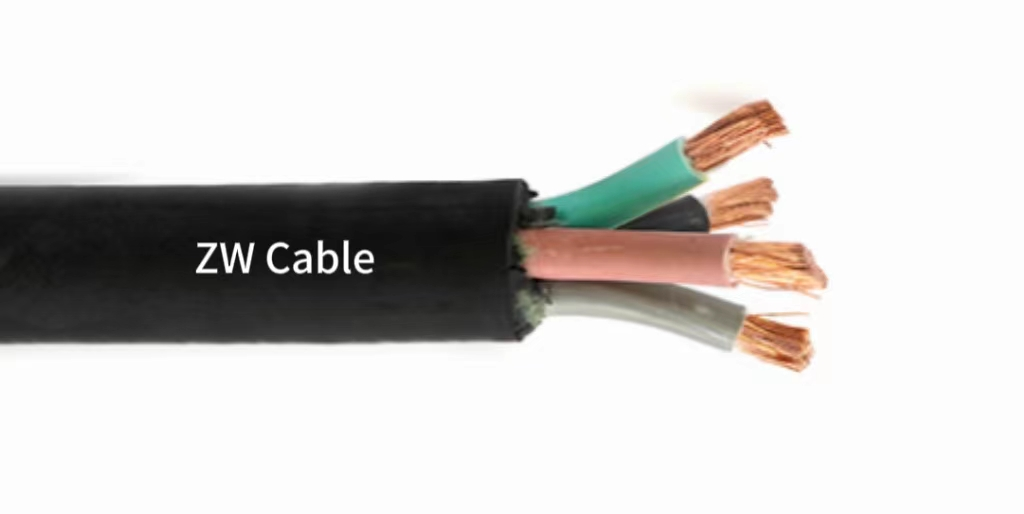

Specialized Cable Manufacturers: For those seeking the best in quality and reliability for their insulating copper wire needs, ZW Cable emerges as the premier choice. Their commitment to excellence, combined with a wide range of products tailored to meet diverse requirements, positions ZW Cable as a leading provider in the industry.

You can make an informed decision before you buy by being aware of the particular requirements of your application and assessing the wire’s quality to determine whether it is right for you.

Copper insulated wire is an indispensable element in the realm of electrical and electronic engineering. It is the unsung hero that powers our daily life, from the enameled copper wire in small motors to the robust insulated cables used in power grids. Understanding its various forms, applications, and the nuances of its market value is crucial for anyone in the field, from engineers to recycles. ZW Cable is a qualified cable manufacturer that can adapt to your requirements. Whether it’s for a delicate electronic device or a major industrial project, choosing ZW Cable ensures that you are equipped with top-tier insulated copper wire, ready to power your endeavors with efficiency and safety.