Vehicles (RVs) have been a popular choice for many years due to their versatility and convenience. So there will be more people’s who will have the question, how do I wiring a trailer wire?

We are knowledgeable in this area and will explain the different types of wiring systems for trailers, from 4-pin connectors to more complicated 7-pin systems. We will also explain the meaning of each trailer wire colors in detail.

Understanding the Basics Trailer Wiring System

Before we dive into the trailer wire color codes, let’s begin with the basics of trailer wiring systems. As an important part of your trailer, the main purpose of trailer wiring harnesses is to provide a vital electrical connection between the towing vehicle and the trailer so that they can operate as an integrated unit for lighting, braking, and other functions.

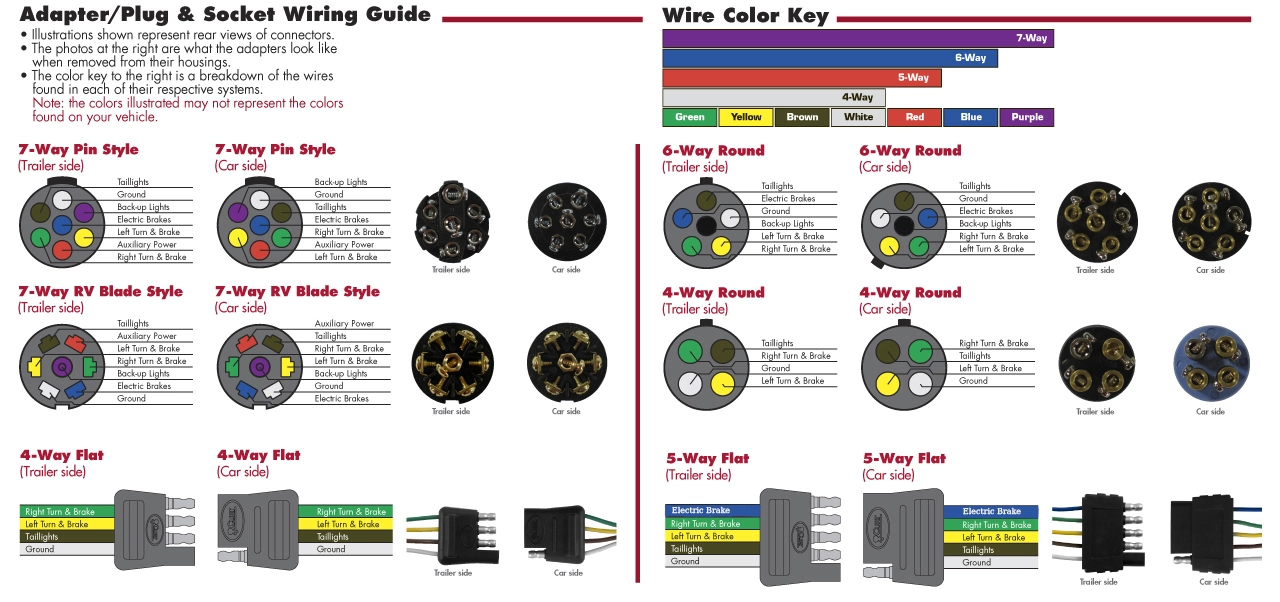

The trailer wiring system consists of wires, connectors, and plugs. Connector on the tow vehicle is called the “female connector” and the wiring harness connector on the RV or trailer is called the “male connector”. Trailer wiring types are primarily differentiated by the number of pins or contacts they have; common ones include 4 pin trailer wiring, 5 wire trailer wiring, 6 pin trailer wiring, and 7 pin wiring to accommodate different trailer types. (European 13 pin trailer wiring is also available).

While the color of trailer wire may vary slightly, there are accepted color codes to keep trailer wiring systems consistent. Next, let’s take a look at the most common trailer wire colors and their respective functions.

Decoding Standard Trailer Wire Colors

Trailer wiring usually contains seven standard colors, which are analyzed as follows:

- White trailer wire: The ground wire that provides a grounding return path by connecting the battery’s negative terminal to the trailer’s frame, thereby enabling the flow of the current back to the battery. The grounding capability is a prerequisite for all other electrical systems in the trailer, including the lighting and braking systems to operate effectively. Therefore, the properly connected white ground wire actually helps keep drivers safe on the road( should be the first one to be connected).

As far as the wire size is concerned, the white ground wire should be the thickest, or as thick as the thickest wire in the system to ensure that the ground wire can handle the total current of all grounding systems. Otherwise, it may not effectively return current, leading to potential electrical problems or even safety hazards.

- Brown trailer wire: supplies power to a trailer’s running lights, taillights, and corner markers. These lights play a vital role in vehicle visibility and safety in low light or nighttime driving conditions. For example, even if a towing vehicle’s headlights are turned off, the running lights powered by brown wire will remain on to illuminate the trailer’s outline, helping other drivers aware of the presence and size of the trailer(small trailers don’t necessarily need all three lights).

The thickness of the brown electrical wire depends on the size of the trailer and the power needs of the lights. If the trailer is big or has many high-powered lights, it needs a thicker brown wire to provide enough power for all the lights. A smaller trailer with fewer or less powerful lights can use a thinner brown wire. Additionally, LED lights use less power than regular halogen lamps, allowing the use of thinner brown wire.

- Yellow trailer wire: lights up the left turn signal and brake light on the trailer when the same lights are turned on in the towing vehicle.

- Green trailer wire: lights up the right turn signal and brake light on the trailer when the same lights are turned on in the towing vehicle.

- Blue trailer wire: trailer brake wiring. When connected to electric brakes, the blue wire sends the towing vehicle’s brake pedal input to the trailer’s braking system, which synchronizes the trailer’s braking with that of the towing vehicle, thereby increasing safety and control. Given that braking is a critical safety function for any vehicle, the blue wire needs to be robust and thick enough.

- Black or red trailer wire: Auxiliary power or battery 12V+. The black (or sometimes red) trailer wire is responsible for providing a 12-volt power supply from the towing vehicle’s battery to the trailer’s onboard systems, such as interior lights, refrigerator, or other appliances that need power when the trailer is not hooked up to external power. This auxiliary power wire plays a critical role in ensuring that the trailer’s amenities can function independently without an external power hook-up, thus making the trailer more flexible and self-sufficient during traveling use.

Trailer wiring systems use different colored wires to perform specific functions, and there could be other trailer wire colors in addition to those listed above. All trailers require basic elements like lighting and grounding; however, whether other wires are included depends on the specific function of the trailer. Next, we’ll enter into trailer wiring diagrams.

Trailer Wiring Diagram (4-Pin, 5-Pin, 6-Pin, 7-Pin)

As we mentioned above, different wiring systems contain different amounts of wire and thus support different functions. Well, in this part we will specifically analyze the different trailer wiring types and provide trailer wiring diagrams and outlet wiring guides. First up are the various connector pin codes or plug wiring diagrams:

Based on the above pin arrangement, you will know how to mate the male and female plugs together. Simply use the pin arrangement as a guide and pair the wires according to their function. The male and female plugs are designed to be symmetrical, so make sure the wires are correctly aligned for color and function.

Next is the specific wiring diagram for trailer lights.

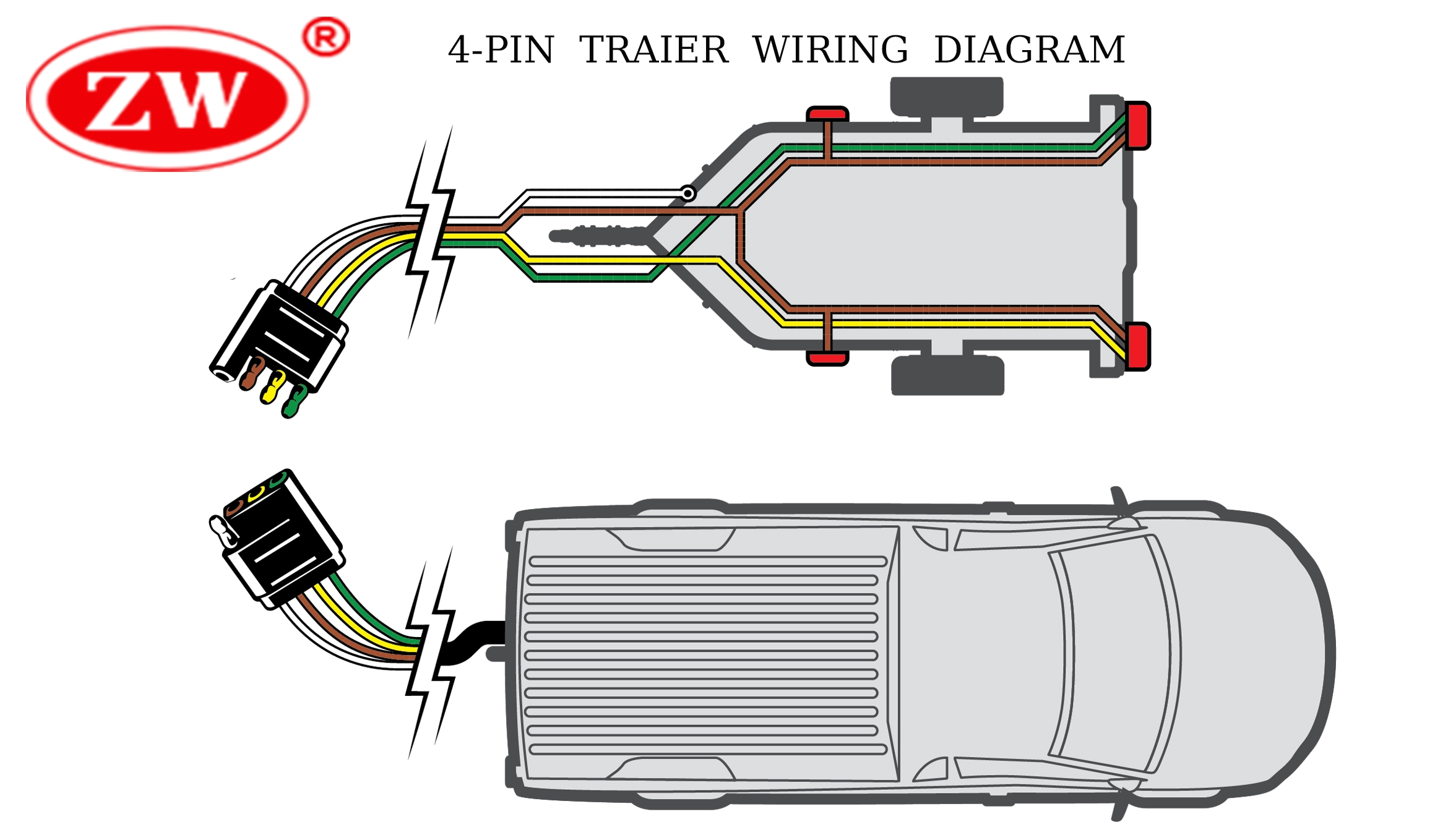

4 way trailer wire diagram:

4-way connector ( Normally Flat or Round): the most basic wiring configuration covers the basic lighting functions and is commonly used for small and lightweight trailers.

- White: Ground

- Brown: Tail/Running Lights

- Yellow: Left Turn Signal/Left Brake Light

- Green: Right Turn Signal/Right Brake Light

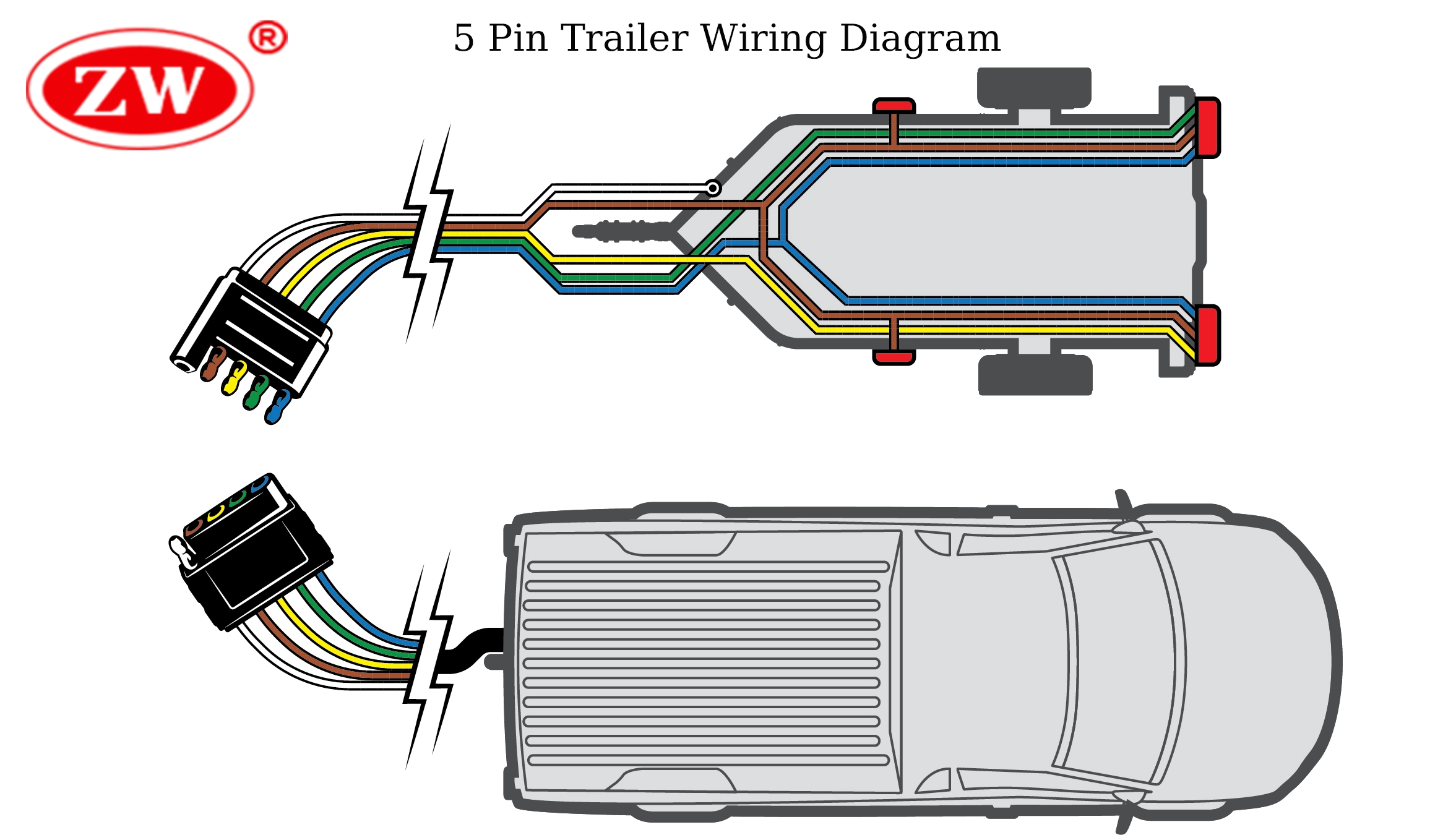

5 wire trailer wiring diagram:

5-way plug adds an additional blue brake wire to the 4-pin setup. This configuration is typically used on heavier trailers equipped with electric brakes to prevent rollover accidents while reversing.

- White: Ground

- Brown: Tail/Running Lights

- Yellow: Left Turn Signal/Left Brake Light

- Green: Right Turn Signal/Right Brake Light

- Blue: Electric brakes

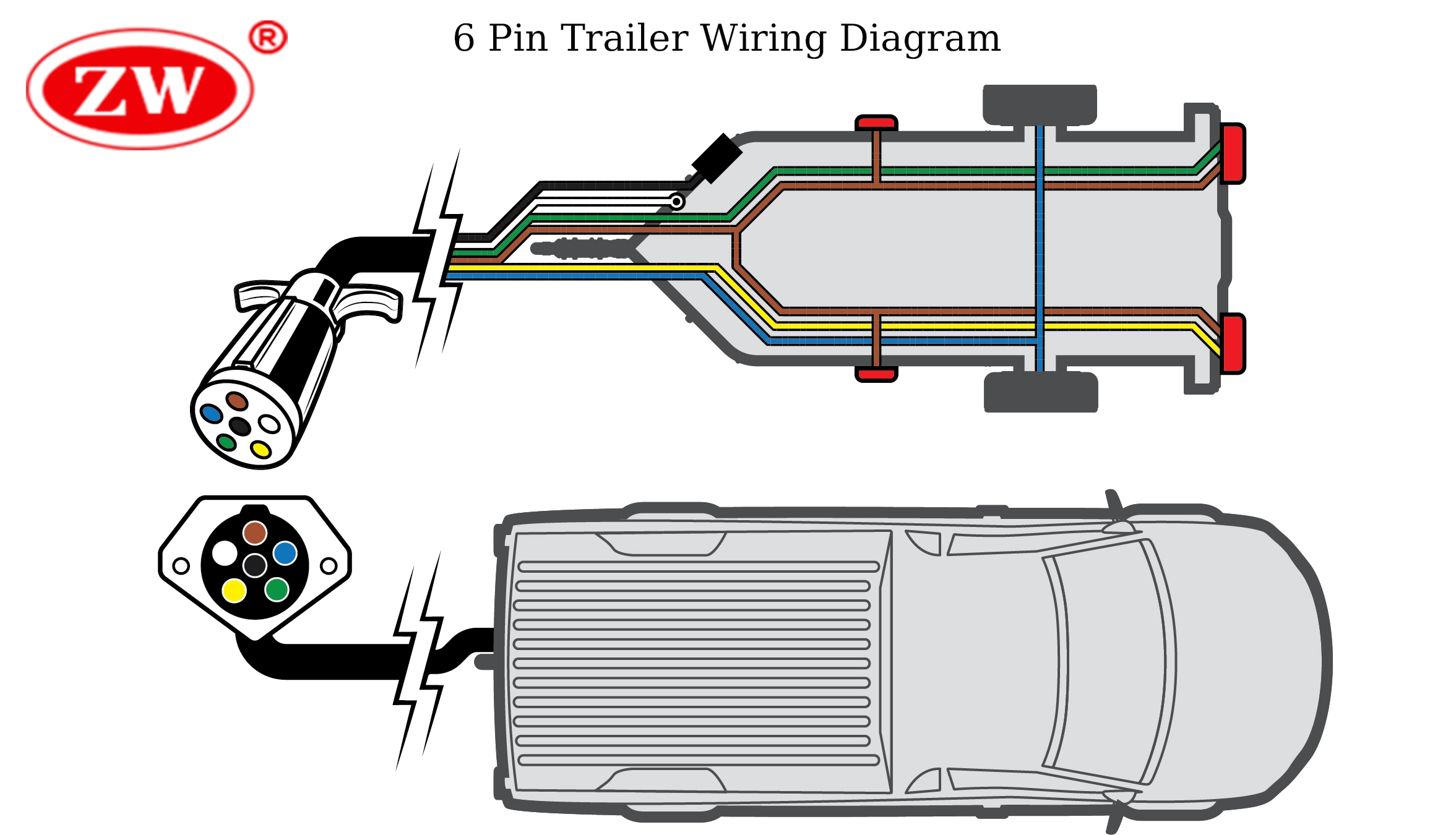

6 pin trailer wiring diagram:

6-way plug (Normally Round) is more common on larger trailers like gooseneck trailers or those with additional power requirements. 6-way wiring adds a black wire to the five-way configuration for auxiliary power or charging the trailer’s battery while being towed.

- Black: Battery + 12v

- White: Ground

- Brown: Tail/Running Lights

- Yellow: Left Turn Signal/Left Brake Light

- Green: Right Turn Signal/Right Brake Light

- Blue: Electric Brakes

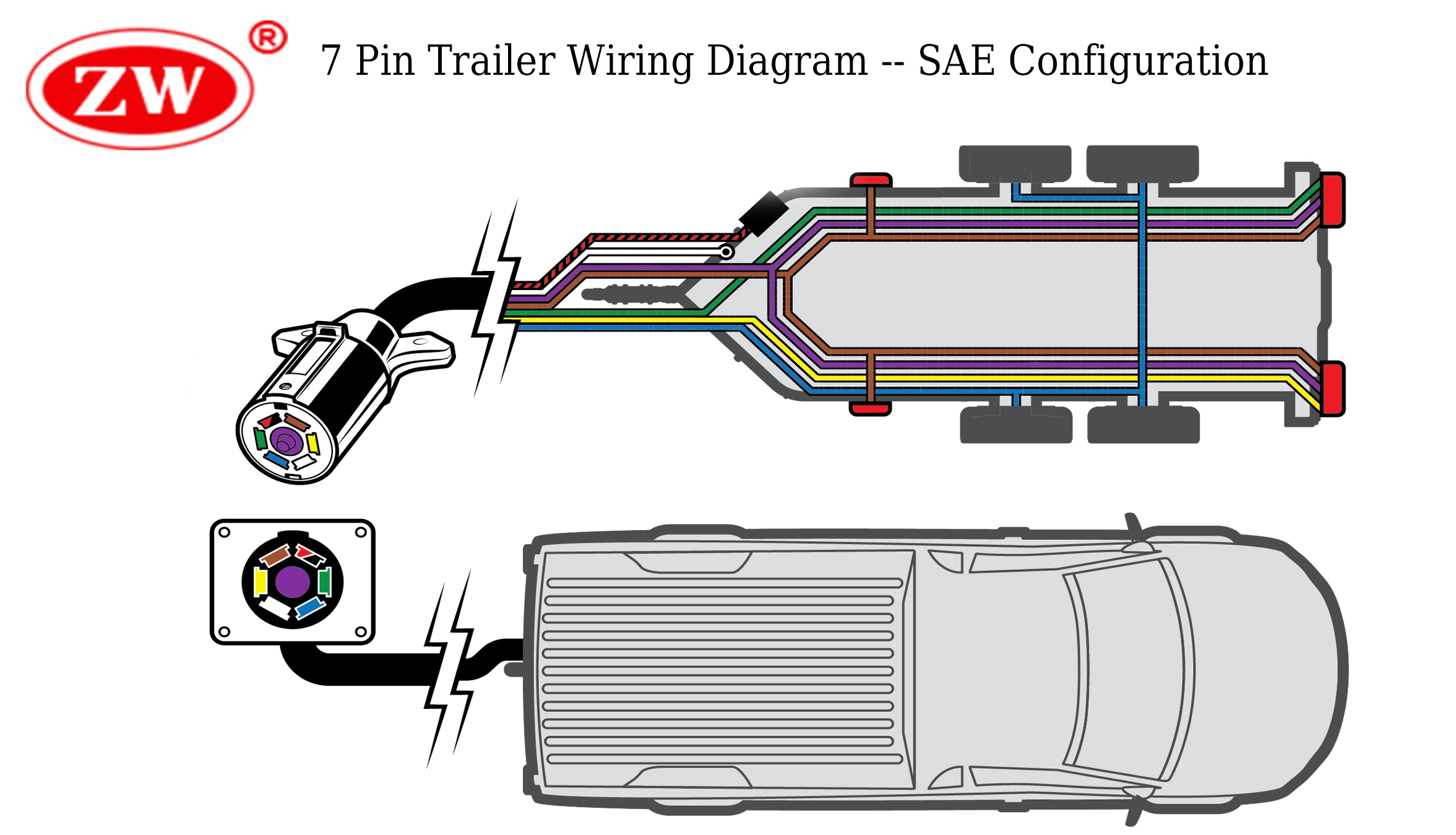

7 way trailer plug wiring diagram(SAE Standard):

7 way trailer wiring is the most comprehensive configuration and is often used for large trailers (7 blade trailer plug is the most commonly used ). Standard 7 pin trailer wiring includes all the wires mentioned in the previous configurations, providing additional connections for electric brakes, auxiliary power, and a backup light or auxiliary function. The additional trailer wire color may be differed by requirement details. 7 blade trailer plug wiring (SAE standard) is typically used for commercial trailers, like cargo trailers and equipment trailers.

- Purple: Reverse Lights

- Blue: Electric Brakes

- Black or Red: Battery +12 volt

- Green: Right turn/brakes

- Yellow: Left turn/brakes

- Brown: Tail/Running Lights

- White: Ground

There is also traditional RV standard 7 blade trailer wiring, however, they changed a lot from the previous.

Color Coding for7-way RV Standard Lights Wiring:

- Green: Tail/running lights

- Red: Left turn/brakes

- White: Ground

- Blue: Electric brakes

- Brown: Right turn/brakes

- Black: Battery +12 volt

- Yellow: Reverse lights

RV standard plug wiring is commonly used on travel trailers and campers in North America (so you can call it 7-pin trailer plug wiring diagram usa). If your trailer light wiring appears disorganized and you really don’t know which trailer wire does what, using a circuit tester pen for identification would be a wise approach.

Trailer wire connectors can generally be adapted or converted to each other with specific adapter devices. For example, if your trailer utilizes a 4-pin connector and your vehicle is equipped with a 7-pin socket, you can use a 4-pin to 7-pin adapter to facilitate the connection. However, adapters can’t add or expand capabilities. That is, even if you change the 4-pin connection to 7-pin connection, you can only utilize the basic lighting circuits and can’t access the other functions allowed by the 7-pin connector. To enable the full functionality, you should upgrade the trailer harness to actually contain the required wiring and circuits. With trailer wire colors and wiring out of the way, let’s take a look at the sizes.

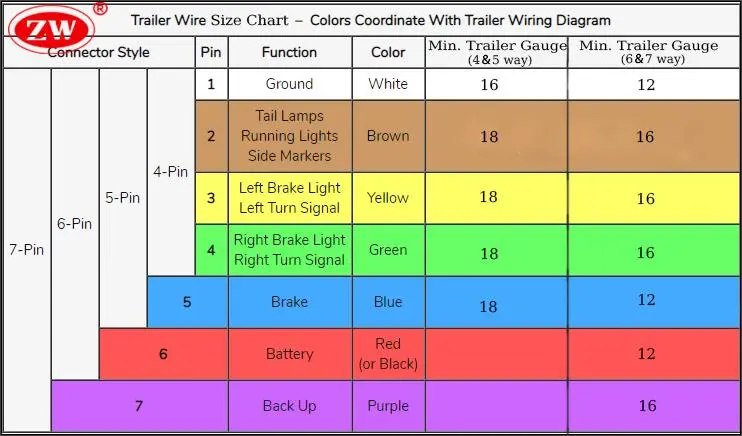

Choose the Right Trailer Wire Gauge

Standard trailer wire gauges usually range from 18 to 12, with 12 gauge being the thickest. Trailer size, power, the number of functions, and the loads the trailer will carry can all affect trailer wire gauge; larger trailers with heavier loads should opt for heavy-duty trailer cable for reliability and safety, like 14 gauge or 12 gauge. For a typically 7-way trailer wire connector, it is recommended that 12-gauge wire be used for the ground wire, battery hot lead wire, and brake wire, with 16-gauge being the minimum recommended standard for the remaining connections. Below is a trailer wire size chart:

The selection of wire gauge for trailer wiring is subjective to the specific requirements and isn’t strictly dependent on the size of the trailer. While larger trailers often require thicker (lower-gauge) wires to accommodate more electrical components and heavier loads, there can be scenarios where smaller trailers may also need larger wire sizes (e.g. with high power-demanding features or components away from power sources ). In this case, it’s wise to consult a professional manufacturer such as ZW Cable.

Pro Tips for Wiring Your Trailer

- Avoid using buck joints and tees: Buck connectors and tee-offs, while convenient, tend to be problematic as they can accumulate moisture and corrode over time. Instead, consider using 7-way junction boxes with protected wire loom for more reliable operation.

- Cable Routing and Protection: Keep wires away from sharp edges, moving parts, and heat sources. If necessary, use wire looms or cable ties to secure them well to prevent vibration-related damage.

- Ground Your Trailer Properly: A common issue with trailer wiring is a poor ground connection; make sure the ground wire is securely connected to a clean, bare metal surface on the trailer frame for effective ground.

- Invest in high-quality grommets and wires: Good-quality grommets protect your wires from the sharp edges of the holes they pass through, while high-quality wires are more durable and ensure reliable connections. Investing in quality components upfront can save you from headaches and repair costs later on.

- Use Heat Shrink Connectors: Opt for heat shrink connectors when splicing wires. Not only do they provide a strong connection, but when heated they form a watertight seal that helps prevent corrosion.

- Keep Spare Fuses: Always carry spare fuses with you. A blown fuse can cause trailer lights or other electrical systems to stop working.

- Regular Maintenance: Regularly inspecting the wiring system and addressing issues immediately is essential. Waiting for a part of the wiring system to break before replacing it can lead to more significant problems and potential safety hazards.

- Be Patient: Wiring trailer lights can be a complex task, especially for beginners. Take your time, double-check everything, and don’t rush the process.

Conclusion

All in all, understanding trailer wire colors, functions, and the appropriate wire gauge is more than technical know-how; it’s fundamentally about ensuring your safety and optimizing the performance of your RV for each journey. Whether it’s powering the brake lights, running lights, or electric brakes, each wire plays a critical role in the overall functioning of your trailer’s system. And the pin and wire coding also makes installation and troubleshooting easier.

Though we provide a comprehensive overview of standard trailer wire colors and gauges, it’s worth noting that variations may exist due to factors such as the manufacturer’s standards, the trailer’s size, and the specific electrical needs of your trailer. Whether you’re wondering how to wire trailer lights or have questions about choosing sizes, ZW Cable is the trailer manufacturer you can trust and has all covered.