In our life, some electrical equipment operates in hot conditions, necessitating the usage of robust wire that is heat resistant. And high temperature wire is a type of electrical wire that is designed to allow electrical appliances to work properly in high temperature environments.

Like ordinary wires, high-temperature wires are designed to transmit power and signals to keep appliances functioning properly. However, high-temperature wire can be used in extreme heat environments, which is one of its main features. Then, let’s learn the meaning of high temp appliance wire.

What does high temperature wire mean?

High temperature wire can work well at high temperatures without melting, deteriorating, or being damaged. This type of electrical wire is made of strong high-temperature-resistant materials, processed by special technology, mainly with high temperature resistance, corrosion resistance, ageing resistance and other characteristics.

Common applications for high temperature electrical wire include aerospace, automotive, electronics, and industrial manufacturing, all of which operate in exceedingly high temperatures or harsh environments. Because it promotes safe and effective operation of the electrical system even at high temperatures and offers dependable power, this type of electrical wire is essential in high-temperature industries.

After knowing the meaning and use of high-temperature wire, next together we will learn about high temperature wire conductor types.

High temperature wire conductor types

Ordinary electrical wire conductors are basically made of pure aluminium and pure copper. But there are different types of conductors for high-temperature appliance wire, which are described separately below.

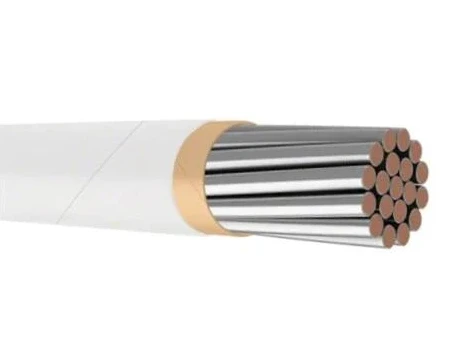

1. Tinned copper is copper with a thin layer of metallic tin wrapped on its surface. The formation of the patina, which is a poor conductor of electricity and raises electrical resistance, is prevented by tinned the outer layer of copper. When copper is exposed to air, the patina will enhance the electrical resistance and prevent the copper from oxidising.

2. Bare copper refers to a pure copper conductor, which means that the copper’s surface is not plated with anything. It is the most common electrical wire conductor and is extremely conductive.

Also Read:Tinned Copper vs Bare Copper: Which One is Better?

3. Pure silver plated copper, a thin layer of silver plated on the outer layer of pure copper conductor, is easy to polish, reflective properties and thermal conductivity, electrical conductivity, welding performance is good, and has high corrosion resistance. This will enhance the performance of the wire and extend the use of time.

4. Nickel plated copper, as the name suggests, is pure copper plated with a thin layer of nickel elements on the outside. Because nickel has a strong ability to passivate, the surface can quickly produce a very thin passivation film, which can resist corrosion from the atmosphere, alkalis, and some acids. In addition, because the nickel plating is relatively hard and stable in the air, it improves the abrasion resistance and service life of the wire.

These are the conductor types for high-temperature wires, and you need to consult a specialist to determine the precise type of conductor to use for high temperature wires. Here’s a look at the high temperature wire insulation types.

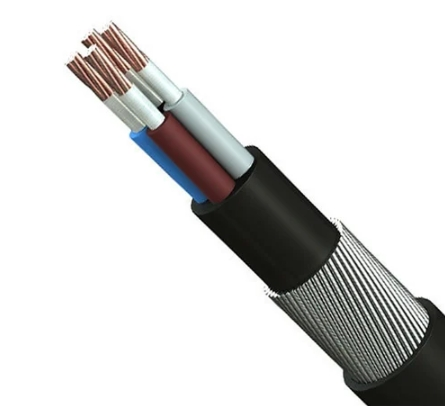

High temperature wire insulation types

There are also different types of high temperature lead wire insulation, and these are the main types analysed below.

1. Perfluoro alkoxy (PFA) insulation: PFA is a type of fluoroplastic with good corrosion resistance, strong high-temperature stability, and can tolerate a maximum temperature of 250 degrees Celsius. It has strong surface tension and good anti-adhesive and abrasion resistance. This material is appropriate for high temperature oven wire.

2. Fluorinated Ethylene Propylene (FEP) insulation: FEP is a chemical that is applied to high-temperature wires as insulation and will make the wire stretch easier and more abrasion resistant. It does not ignite, stops the spread of flames and can withstand a maximum temperature of 200 degrees Celsius. It is also resistant to chemicals.

3. Polytetrafluoroethylene (PTFE) insulation: PTFE is a polymer that is both heat and cold-resistant and can operate between -60 and 260 degrees Celsius. For extreme operating environments, this material is well suited for use as electrical wire insulation. It is chemically and abrasion resistant, and it has good electrical conductivity.

4. Silicone insulation: Silicone has strong waterproof and moisture-proof performance, high heat resistance, the highest working temperature up to 200 degrees Celsius, excellent chemical stability, can be resistant to high pressure, ageing resistance and long service life. And it is soft and easy to carry out complex installations. At the same time also has good resistance to acid, alkali, and anti-fungal properties, can be resistant to hot and humid environments and is resistant to a variety of oil and grease characteristics. Silicone is also often used in electrical wire insulation.

![]()

This is an introduction to the several types of insulation involved in high temperature wire. If you need to wire high temperature wire, consult a professional electrician to choose exactly the types of high temperature wire high temperature insulated wire connectors, and high temperature wire connectors to use. After that, let’s analyse the high temperature wire gauge.

High temperature wire gauge

High-temp wire is used in different application scenarios, and different specifications will be used. The most commonly used is high temperature wire 12 awg. The following is the high-temperature wires gauge.

| Gauge | Outer Diameter (mm) | Max. Conductor Resistance DC 20℃(Ω/km) | Packing(m) |

| 10 gauge high temperature wire | 4.03 | 3.546 | 305 |

| 12 gauge high temperature wire | 3.47 | 5.64 | 305 |

| 14 gauge high temperature wire | 2.87 | 8.96 | 305 |

| 16 gauge high temperature wire | 2.52 | 14.6 | 305 |

| 18 gauge high temperature wire | 2.17 | 23.2 | 305 |

After knowing the gauge of high temperature wire, we can find out the high-temperature wire vs heat-resistant wire.

High-temperature wire VS Heat-Resistant wire

They both can withstand high temperatures and are interchangeable, which is something they both have in common. But they still differ from one another.

Firstly, high-temperature wire refers to the wire at least 150℃ can work stably, but heat-resistant wire refers to the wire insulation and shielding layer that has the ability to resist heat.

Secondly, the working temperature of the heat-resistant wire is between 90 and 150℃, while high-temperature wire supports at least 150℃ normal work. The high-temperature wire is stronger than heat-resistant wire, so the high-temperature cable standard is higher than the manufacturing standard of heat-resistant wire.

Finally, heat-resistant wire is a general term with a wide range. In contrast, high-temperature wire has a more specific range and is a type of heat-resistant wire.

It’s important to keep in mind that the precise composition, design, and intended usage of high-temperature wire can affect its temperature ratings and capabilities. Manufacturers provide specifications and temperature limits for their wires, and it’s important to select the appropriate wire based on the specific requirements of the application to ensure reliable and safe operation.

In addition, a variety of factors can make a difference, and the specific specifications of high temperature and heat resistant wires have to be chosen based on the actual situation. After understanding, you may have questions about the application of high-temperature wire, so when will you use high-temperature wire?

When should I use a high temperature wire?

High-temperature wires are rated for normal and stable operation at elevated temperatures, with unaffected signal or power transmission performance, and are also guaranteed to have a long service life.

In the industrial environment, steel or glass manufacturing and other high-temperature processes require wires that can withstand high temperatures.

Heating appliances. Some heating appliances will use high-temperature wire, such as electric grills, furnaces and kilns for firing porcelain, etc., use high-temperature wire to keep the appliances working properly.

In the aerospace industry, high temperature wire is used to prevent aircraft failures, as the speed of an aircraft or other vehicle during flight can cause high temperatures in critical areas such as the engine.

In the automotive industry, the car in the process of operation will make the car’s engine, exhaust system and turbocharger temperature, the use of high-temperature wire can keep the vehicle’s electrical connections stable.

In addition, some high-power equipment will also use high-temperature wire to make electrical appliances run smoothly. At the same time, when choosing high-temperature wires, people need to make clear the specific temperature and the material used for the wire. High-temperature wire insulation and sheath materials are usually PFA, PTFE and silicone.

If in the above scenario, high temperature wire is a good choice. You also need to consult a professional electrician for special cases.

Conclusion

Above are the related knowledge about high-temp wires, people can learn the conductor types, insulation types, gauges, applications and the contrast of high-temperature wire vs heat-resistant wire. In practical terms, high temperature wire near me and help me get some work done.

If you want to buy high temperature wire, you can contact ZW Cable. We can produce the high-quality of high temp wires. ZW Cable can also produce other cost-effective electrical wires you need, which are long-lasting and not easily damaged.