As a popular type of armored cable, AWA cable provides dependable solutions for a wide range of complex electrical projects while being cost-effective. If you intend to purchase this versatile and reliable cable, read this blog for its definition, application, size, and how it differs from SWA cables.

What is AWA cable?

AWA cable meaning aluminum wire armour cable, is a commonly used armored cable in distribution systems. Aluminum wire armor layer provides mechanical protection for the cable, making it resistant to corrosion, physical damage, and even rodents.

AWA cable is typically used in low-voltage and medium-voltage applications where cable damage may occur. Its armoring not only reduces the risk of cables being torn or squeezed, but it can also be used to protect AWA armored cables in AC systems from overheating. When installing aluminum wire armor cable, AWA cable glands can be used to secure and seal cable ends entering enclosure or equipment from water, dust, and other contaminants, and can relieve cable strain.

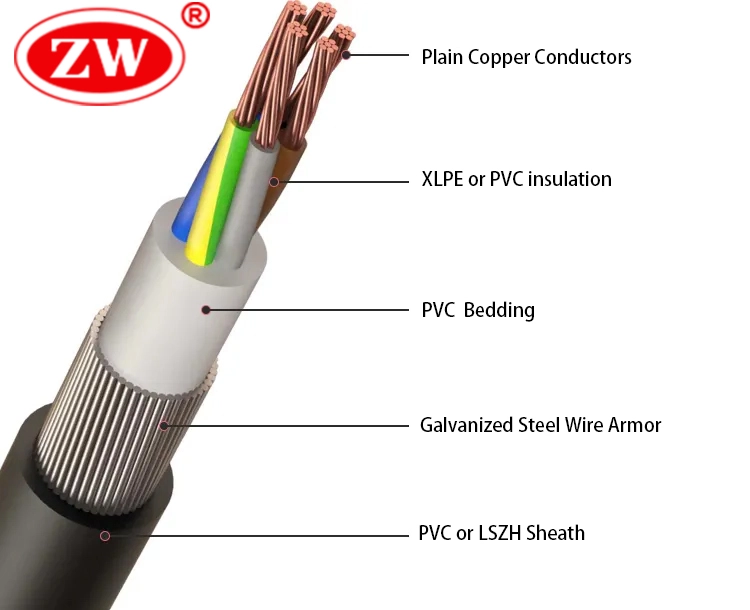

AWA armoured cables are constructed as follows:

- Conductor: plain stranded copper or aluminum

- Insulation: often made of PVC (Polyvinyl Chloride) or XLPE (Cross-Linked Polyethylene), which provides electrical insulation and protects against electric shock.

- Bedding: also known as inner sheath, serving as a protective barrier between the insulation and armor, often made of PVC. It enhances cushioning and provides a smooth surface for armor.

- Armor: consists of a layer of aluminum wire spirally wrapped around the cable.

- Sheath: a final layer of protection for the cable, often made of PVC or LSZH.

With an understanding of aluminum wire armor cable definition and construction, let’s take a look at its specific applications.

Learn More: Exploring Armoured Cable: Benefits, Types, And Installation Requirements

When Do We Use AWA Cable?

Aluminum wire armored cables are typically used in applications where mechanical protection, durability, and resistance to environmental factors are critical. Some typical applications are as follows:

- Indoor Electrical Wiring: Aluminum wire armored cable can be used for interior wiring in residential, commercial, and industrial buildings, like power distribution, lighting, and control.

- Outdoor Overhead Installation: Due to the light weight of aluminum wire armored cables, they are often used for outdoor overhead installations (that is, the cable is suspended on poles or other structures).

- Industrial Settings: Corrosion resistance of xlpe AWA electrical cable makes it suitable for use in environments where moisture, chemicals, or other corrosive substances are present, for example, marine applications, sewage treatment plants, and industrial facilities with corrosive atmospheres.

- Low Voltage Power Distribution: AWA cables can be used for low-voltage distribution in residential and industrial environments, as they are advantageous in applications where power demand is relatively low and cost-effectiveness is important.

- Instrumentation and Control Systems: in instrumentation and control systems, AWA armored cables are used to transmit measurement, monitoring, and control signals reliably; commonly found in manufacturing, the oil and gas industry, and process control.

- Communication networks: in a variety of telecommunications systems, such as telephone networks, data transmission, and Internet connectivity, aluminum wire armored cables are used to transmit and handle high-frequency signals.

Depending on the application, AWA cables are available in different sizes.

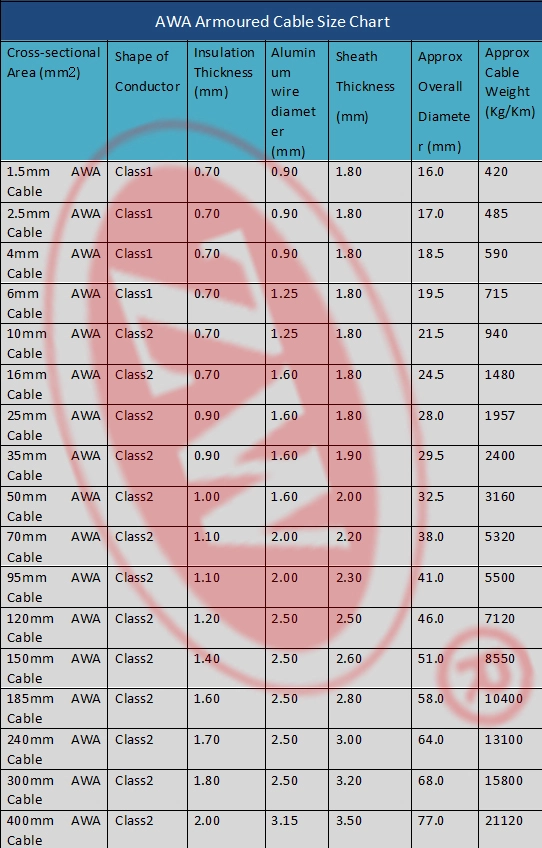

AWA cable size chart

The sizes of single-core AWA cable can be found in the following cable technical specifications chart, which provides information on the nominal cross-sectional area of the cable, the cable’s outside warp, cable weight, and the diameter of the aluminum wire armor. ZW cable also provides information on the thickness of the insulation, conductor material and standards:

According to the above table, choose the right awa cable specification for your application to achieve a secure and reliable connection. Now let’s check out the comparison between two common types of armored cable.

What is the difference between AWA and SWA Cable?

AWA (Aluminium Wire Armored) and SWA (Steel Wire Armoured ) cable are two common types of armored cable that can be used in various settings, especially where additional protection is required. The main difference between them lies in the armoring material, SWA uses steel wire, while AWA uses aluminum wire; their specific application differences are as follows:

- Aluminium Wire Armored Cable:

AWA cables are armored with aluminum wire in an inner jacket, are lighter in weight compared to SWA cables, and are therefore preferred in applications where lighter weight is required. In addition, since aluminum is less susceptible to electromagnetic fields than steel wire, AWA cables may be a better choice in applications where electromagnetic compatibility is a concern. However, aluminum wires are generally not as strong as steel wires, so AWA electrical cables may not offer the same protection from mechanical stress as SWA cables.

- Steel Wire ArmouredCable:

SWA cables use galvanized steel wire armoring within the inner sheath. The main advantage of these cables is high strength, which provides excellent protection against harsh physical conditions. As a result, SWA cables are commonly used in underground, construction, and industrial settings. However, steel wire armored cable could be difficult to install because of the large steel wire mass and the relatively heavy weight.

Overall, SWA and AWA cables are designed with different application requirements and environmental conditions. AWA cables are favored for their lightweight and electromagnetic compatibility benefits at low cost, while SWA cables are renowned for their strength and robust protection. The choice of cable type needs to be weighed against the specific application environment and requirements.

Bottom Line

In summary, aluminum wire armored cables play an essential role in electrical installations. Its aluminum armoring makes it suitable for multiple challenging environments, providing excellent mechanical protection while being lighter than traditional steel armored cables, making it easier to handle and install.

However, when selecting AWA cable sizes, careful consideration should be given to the specific requirements of the electrical system, such as current loading and installation conditions, and if necessary, expert advice should be sought, e.g. for ZW cable. As a specialized cable manufacturer, ZW Cable offers a wide range of high-quality compliant cables, which can be customized, and free samples provided.