As a kind of clean, abundant, and renewable power source, solar energy is increasingly integrated into our daily lives, and solar cable plays an essential role in PV power generation systems. Want to learn more about solar panel wires? Join us for an in-depth look.

What is solar cable?

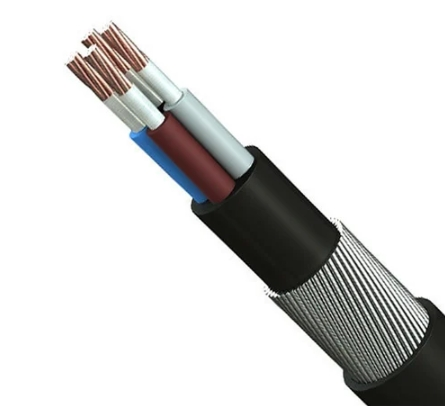

Solar cable, or photovoltaic (PV) cable, is a special cable designed for solar power systems. The solar power system works by catching sunlight with panels and converting it into direct current. It is then converted into usable alternating current through inverters and finally supplied directly to the grid or stored in a battery for later use. It is the solar cables that interconnect intrinsic components, including solar panels, inverters, charge controllers, and batteries, enabling the transmission of electricity, and it can be said that the quality of solar cables directly affects the power generation efficiency of photovoltaic systems. Common types of solar cables are single-core solar cable, twin solar cable, and armored solar cable.

PV wire typically consists of stranded tinned copper conductors surrounded by XLPO insulation and sheath and are color-coded (red and black). Double XLPO construction makes solar wire suitable for outdoor conditions, resisting UV rays, temperature extremes, ozone, and moisture while efficiently transmitting direct current electricity generated by solar panels. To increase safety and flexibility in PV systems, solar cable connectors are also an important part; the most common type of solar panel connectors are mc4 connectors. The solar cable hs code is 8544492100.

Understanding the above solar cable specification, the following comes as the top priority, i.e., how to choose the right cable size.

What size solar cable do I need?

To determine the proper solar panel wire size, you need to consider the power, amperage, cable length, and voltage drop, which you can do by following these steps:

- Find out what the maximum power of solar panels is.

- Calculate the amperage by dividing the wattage by the voltage of the panel; common voltage range for residential solar panels is 20 to 40 volts, like 12v, 24v, and 36v.

- Determine the required cable length.

- Divide voltage by current to obtain the resistance.

- Using this solar cable size calculator: S=ρ×L/R, where S is cross-section area, ρ is resistivity(copper resistivity=0172, Aluminum resistivity=0.0283), L is cable length, and R is resistance.

Choose a size slightly larger than the result; whether it’s solar DC cable or solar AC cable, the most popular cable sizes are 2.5mm, 4mm, and 6mm:

| Specification | Current Capacity | Running Distance | Diameter (mm) |

|---|---|---|---|

| PV Wire 10 AWG | Up to 30A | 13 Meters | 5.9 |

| 4mm2 Solar Cable | Up to 44A | 15 Meters | 5.7 |

| 6mm2 Solar Cable | Up to 55A | 20 Meters | 6.5 |

Based on the chart above, you can pick out the appropriate cable sizing for solar system. The rule of thumb is to select 4 mm² for loads below 20A and 6 mm² for loads above 20A. If you want to save cost, reduce bridging gaps between components, and ease installation, solar extension cable is also a good choice. Next, we will uncover why solar panel wires are so special compared to regular cables.

What’s the difference between solar cable and normal cable?

Pv cable and normal cable differ in their construction, temperature, and voltage rating to suit their respective requirements. Here are the key differences between solar power cable and normal cable:

Construction:

Solar power cable: insulated with XLPE, which is flexible, moisture-proof, flame retardant, and resistant to UV (ultraviolet) radiation and extreme weather, making them suitable for outdoor PV system use.

Normal cable: typically adopts PVC insulation and is not equipped with the same level of weather resistance; typically used for general electrical wiring purposes in buildings and other applications.

Temperature Rating:

Solar power cables can handle wider range of temperatures to accommodate high-temperature environments in which solar panels are installed; they are rated from -40°C to 90°C or higher. Normal cables, though they can withstand slightly higher temperatures for short periods, are less durable in extreme temperature environments.

Voltage Rating:

Solar panel cords have specific voltage ratings, such as 600V or 1,000V, to align with the voltage levels typically found in solar power systems, whereas normal cables encompass a broader range of voltage levels to suit various electrical applications, like high-voltage, medium-voltage, and low-voltage.

Environmental Compatibility:

Solar power cables do not contain harmful substances like lead or cadmium and do not pollute the environment, making them safe for use in solar power systems. In contrast, normal electrical wires may contain harmful substances.

All in all, solar panel connection cables are designed to withstand the special conditions of solar installations and provide better durability and performance in PV systems than ordinary cables. The latter is more suitable for general indoor and outdoor electrical wiring but may not provide the same level of protection against UV rays and inclement weather. Therefore, there is no need to swap these two cables unless necessary. After this, let’s take a look at some comparisons between copper and aluminum solar wires.

Can I use Aluminium Solar cable for solar panel?

Generally speaking, aluminum solar cables can be used for solar panels, only the specifications need to be a little larger than copper solar cables. This is ascribed to aluminum’s lower electrical conductivity compared to copper and requires a thicker cross-sectional area to carry the same amount of current without excessive voltage drop, for example, 4mm copper cable needs to be replaced by 6mm aluminum cable.

To make a better choice, it’s necessary to check out the differences between copper and aluminum conductors in solar panel wires:

- Resistivity: The resistivity of copper-core PV cables is 1.68 times lower than that of aluminum-core PV cables, resulting in lower energy consumption and higher efficiency.

- Stability and fatigue resistance: Aluminum core is easy to oxidize and corrode, yet copper core is more stable and resistant to oxidation; copper is less prone to breakage by repeated bending, while aluminum is not. With regard to the elasticity index, copper is also approx. 1.7 to 1.8 times higher than aluminum.

- Heat generation: In the case of same current, the heat generation of copper-core PV cable of same cross-section is much smaller than that of aluminum alloy cable, enabling safer operation.

- Weight: Aluminum wire is significantly lighter than copper electrical wire, which can be advantageous in long cable runs, as it reduces the overall weight and strain on the supporting structure.

- Cost: Aluminum typically costs less than copper, making it an attractive option for budget-conscious solar installations.

In summary, while it is true that copper cores have a performance advantage over aluminum cores, larger aluminum alloy solar wires can still be used effectively for many general solar applications, achieving efficient power transmission. So how long do solar wires last?

Learn More: Copper vs Aluminum Wire: Understanding the Differences and Making the Right Decision.

Solar cable life expectancy

Theoretically, high-quality solar cables installed according to best practices and properly maintained can have a life expectancy of up to 70 years, which is much longer than ordinary cables ( 5 to 8 years with optimal maintenance). However, cable quality, operating temperature, and environmental factors of the solar installation all have an impact on cable life. Therefore, to maximize the life of solar wires, in addition to following installation specifications and performing regular solar cable maintenance, you should choose a trusted solar cable manufacturer.

Bottom line

The above could give you an in-depth understanding of cable for solar panels; and you may find no matter is size selection, service life, or cable comparison, they all emphasize the quality of solar cable. In this regard, ZW cable is your preferred choice, for all of its production is subjected to rigorous testing, in line with international standards, and provides warranty service. ZW sincerely welcomes your inquiries.